Table of Contents

Advantages of Using Automatic Rice Multi-Head Weighing Filler Screw Capping Machine Line

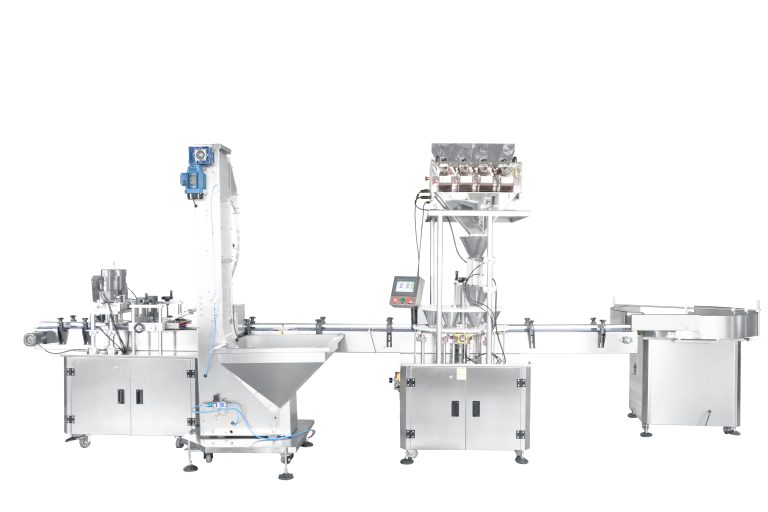

In the food packaging industry, efficiency and accuracy are crucial factors in ensuring the quality and consistency of the products being produced. One of the key components in achieving this is the use of automatic rice multi-head weighing filler screw capping machine lines. These advanced machines offer a range of advantages that make them an essential investment for businesses looking to streamline their production processes and improve overall output.

One of the primary advantages of using an automatic rice multi-head weighing filler screw capping machine line is the high level of precision and accuracy it offers. These machines are equipped with multiple weighing heads that are capable of measuring and dispensing precise amounts of rice into individual packaging units. This level of accuracy ensures that each package contains the correct amount of product, reducing the risk of under or overfilling and ultimately improving the overall quality of the final product.

In addition to precision, automatic rice multi-head weighing filler screw capping machine lines also offer significant improvements in efficiency and productivity. These machines are capable of handling large volumes of rice at a rapid pace, significantly reducing the time and labor required for packaging. This not only increases the overall output of the production line but also allows for greater flexibility in meeting customer demand and responding to market fluctuations.

Furthermore, the automation of the filling and capping processes reduces the potential for human error, further enhancing the overall quality and consistency of the packaged rice. By eliminating the need for manual intervention, these machines minimize the risk of contamination and ensure that each package meets the required standards for hygiene and safety.

Another key advantage of using automatic rice multi-head weighing filler screw capping machine lines is the versatility they offer in packaging options. These machines are capable of handling a wide range of packaging formats, including bags, pouches, and containers of various sizes. This flexibility allows businesses to adapt to changing market demands and offer a diverse range of products without the need for significant retooling or reconfiguration of the production line.

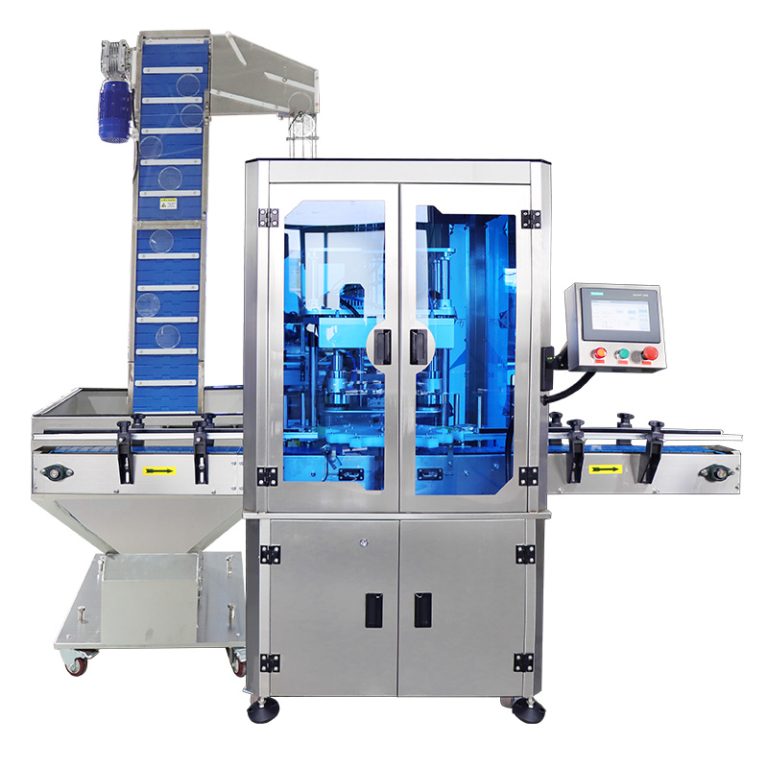

Additionally, the integration of screw capping technology in these machine lines ensures a secure and reliable seal for each package, further enhancing the shelf life and freshness of the packaged rice. This is particularly important for businesses looking to expand their distribution channels and reach new markets, as it ensures that the product remains in optimal condition throughout the supply chain.

In conclusion, the advantages of using automatic rice multi-head weighing filler screw capping machine lines are clear. From improved precision and efficiency to enhanced versatility and packaging options, these advanced machines offer a range of benefits that can significantly impact the overall success and competitiveness of a business in the food packaging industry. By investing in this technology, businesses can streamline their production processes, improve product quality, and ultimately, meet the evolving needs of their customers.

How to Choose the Right Automatic Rice Multi-Head Weighing Filler Screw Capping Machine Line for Your Business

In today’s fast-paced business environment, efficiency and accuracy are key factors in the success of any production line. When it comes to the food industry, particularly in the packaging of rice, an automatic rice multi-head weighing filler screw capping machine line can significantly improve the speed and precision of the packaging process. However, with so many options available in the market, choosing the right machine line for your business can be a daunting task. In this article, we will discuss the key factors to consider when selecting an automatic rice multi-head weighing filler screw capping machine line for your business.

First and foremost, it is essential to assess the production capacity of your business. The machine line you choose should be able to meet the demands of your production line without causing any bottlenecks. Consider the volume of rice that needs to be packaged on a daily, weekly, and monthly basis, and choose a machine line that can handle that capacity efficiently.

Another important factor to consider is the level of automation required for your production line. Automatic rice multi-head weighing filler screw capping machine lines come in various levels of automation, from semi-automatic to fully automatic. The level of automation you choose will depend on the size of your production line, the skill level of your operators, and the level of precision required in the packaging process.

Furthermore, it is crucial to consider the accuracy and precision of the weighing and filling mechanism of the machine line. The machine line should be able to weigh and fill each package of rice with consistent accuracy to ensure uniformity in the final product. Look for a machine line that utilizes advanced technology to achieve precise weighing and filling, such as load cell technology and digital controls.

In addition to weighing and filling, the screw capping mechanism of the machine line is another critical aspect to consider. The machine line should be able to cap each package of rice securely and efficiently to prevent any spillage or contamination. Look for a machine line that offers a reliable and adjustable screw capping mechanism to accommodate different sizes and types of packaging.

Moreover, it is important to consider the overall footprint of the machine line and its compatibility with your existing production infrastructure. The machine line should be able to fit into your production facility without causing any disruptions to the workflow. Consider the layout of your production line and choose a machine line that can be seamlessly integrated into the existing setup.

Lastly, it is essential to consider the after-sales support and maintenance services offered by the manufacturer of the machine line. Look for a reputable manufacturer that offers comprehensive training for your operators, as well as prompt technical support and spare parts availability. A reliable after-sales support system is crucial for the smooth operation and longevity of your machine line.

In conclusion, choosing the right automatic rice multi-head weighing filler screw capping machine line for your business requires careful consideration of various factors, including production capacity, level of automation, weighing and filling precision, screw capping mechanism, compatibility with existing infrastructure, and after-sales support. By taking these factors into account, you can select a machine line that will enhance the efficiency and accuracy of your rice packaging process, ultimately contributing to the success of your business.