Table of Contents

Benefits of Using Automatic Rice Canning Line with Nitrogen Gas Flushing for Plastic Cans

In the food industry, packaging plays a crucial role in preserving the quality and freshness of products. When it comes to packaging rice, using plastic cans has become a popular choice due to their durability and convenience. However, to ensure that the rice stays fresh for a longer period, it is essential to invest in an automatic rice canning line with nitrogen gas flushing.

Nitrogen gas flushing is a process where nitrogen gas is injected into the packaging before sealing to displace oxygen. This helps in creating a modified atmosphere inside the package, which slows down the oxidation process and prevents the growth of bacteria and mold. By using nitrogen gas flushing, the shelf life of the rice can be significantly extended, ensuring that customers receive a high-quality product.

One of the key benefits of using an automatic rice canning line with nitrogen gas flushing is the efficiency it offers. With automation, the entire packaging process is streamlined, reducing the need for manual labor and increasing productivity. This not only saves time but also ensures consistency in the packaging process, leading to a higher quality end product.

Furthermore, nitrogen gas flushing helps in maintaining the color, texture, and flavor of the rice. Oxygen is known to cause oxidation, which can lead to discoloration and off-flavors in the rice. By replacing oxygen with nitrogen gas, the rice is protected from these harmful effects, ensuring that it looks and tastes fresh for a longer period.

Another advantage of using nitrogen gas flushing is the enhanced safety it provides. By creating a modified atmosphere inside the package, the growth of harmful bacteria is inhibited, reducing the risk of foodborne illnesses. This is especially important in the case of rice, which is a staple food for many people around the world.

In addition to these benefits, using an automatic rice canning line with nitrogen gas flushing can also help in reducing food waste. By extending the shelf life of the rice, less product is wasted due to spoilage, leading to cost savings for manufacturers and retailers. This not only benefits the bottom line but also contributes to a more sustainable food supply chain.

Overall, investing in an automatic rice canning line with nitrogen gas flushing for plastic cans is a wise decision for food manufacturers looking to improve the quality and shelf life of their products. By utilizing this technology, they can ensure that their rice stays fresh, safe, and appealing to customers. With the efficiency, consistency, and safety benefits it offers, nitrogen gas flushing is a valuable tool in the packaging process.

Step-by-Step Guide on How to Set Up an Automatic Rice Canning Line with Nitrogen Gas Flushing for Plastic Cans

Setting up an automatic rice canning line with nitrogen gas flushing for plastic cans can greatly improve the efficiency and quality of your rice packaging process. This step-by-step guide will walk you through the process of setting up this system to ensure that your rice is properly sealed and preserved.

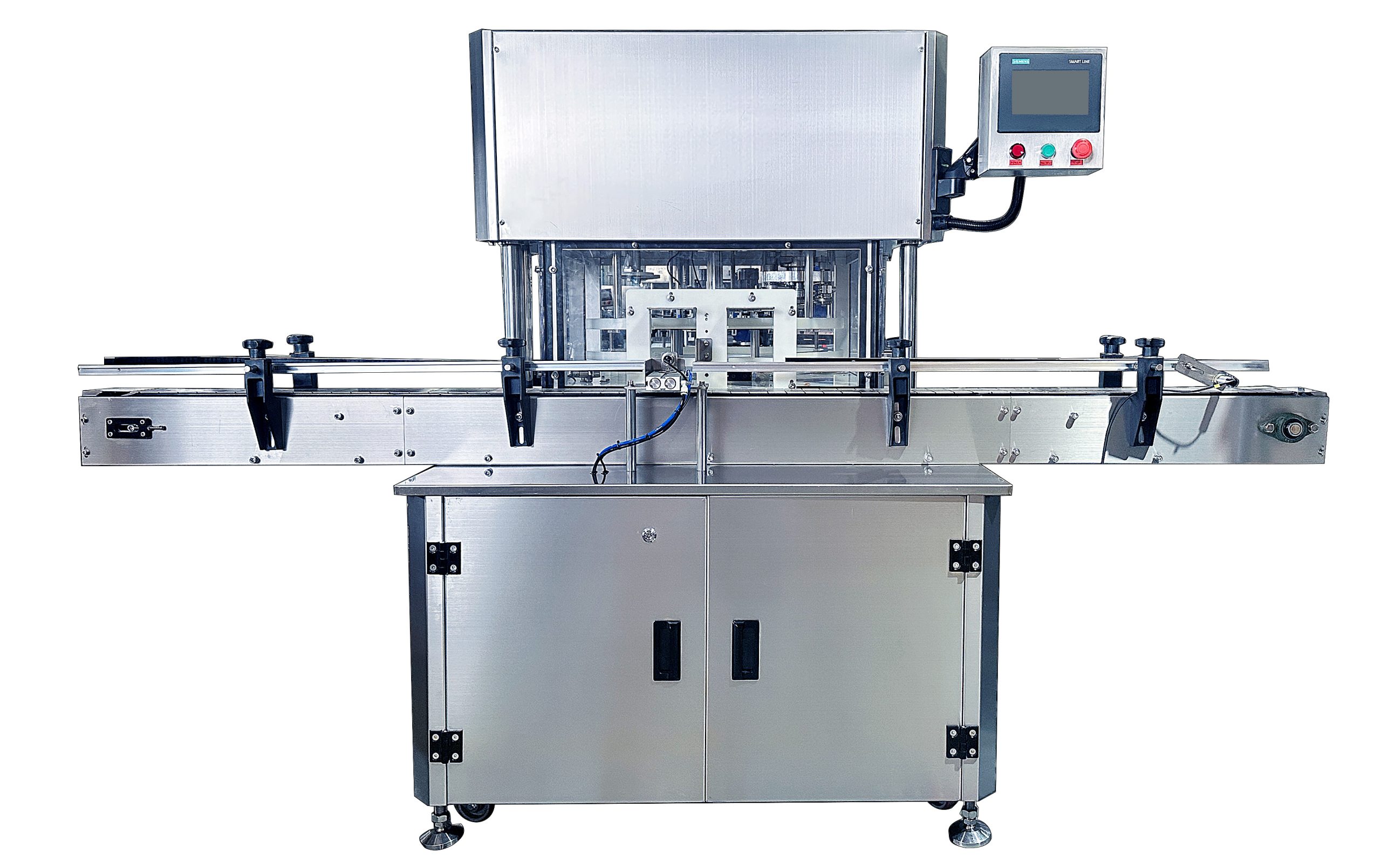

The first step in setting up an automatic rice canning line is to ensure that you have all the necessary equipment. This includes a canning machine, nitrogen gas flushing system, conveyor belts, and sealing machines. It is important to choose high-quality equipment that is suitable for rice packaging to ensure that your product is properly sealed and preserved.

Once you have all the necessary equipment, the next step is to set up the canning machine. This machine will fill the plastic cans with rice and seal them to ensure that they are airtight. Make sure to follow the manufacturer’s instructions for setting up the machine to ensure that it operates correctly.

After setting up the canning machine, the next step is to install the nitrogen gas flushing system. This system will flush out the oxygen from the cans and replace it with nitrogen gas to preserve the rice and prevent oxidation. Make sure that the nitrogen gas flushing system is properly connected to the canning machine and set to the correct pressure for rice packaging.

Once the nitrogen gas flushing system is installed, the next step is to set up the conveyor belts. These belts will transport the cans from the canning machine to the sealing machines. Make sure that the conveyor belts are properly aligned and have the correct speed to ensure a smooth and efficient packaging process.

Finally, the last step is to set up the sealing machines. These machines will seal the cans to ensure that they are airtight and properly preserved. Make sure to follow the manufacturer’s instructions for setting up the sealing machines to ensure that they operate correctly and seal the cans properly.

In conclusion, setting up an automatic rice canning line with nitrogen gas flushing for plastic cans can greatly improve the efficiency and quality of your rice packaging process. By following this step-by-step guide, you can ensure that your rice is properly sealed and preserved for maximum freshness and quality. Make sure to choose high-quality equipment and follow the manufacturer’s instructions for setting up each component of the canning line to ensure a smooth and efficient packaging process.