Table of Contents

Exploring the Efficiency of Automatic Powder Tin Can Packing Line

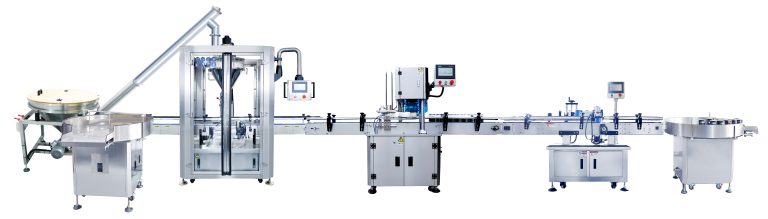

The automatic powder tin can packing line is a revolutionary innovation in the packaging industry that has significantly enhanced efficiency and productivity. This advanced technology has been designed to automate the entire process of packing powder into tin cans, thereby reducing manual labor, increasing speed, and ensuring precision.

The automatic powder tin can packing line is a comprehensive system that integrates several machines, each performing a specific task. The process begins with the powder filling machine, which accurately measures and fills the powder into the tin cans. This machine is equipped with advanced sensors and control systems that ensure precise filling, eliminating wastage and ensuring consistency.

Following the filling process, the cans are then transferred to the sealing machine. This machine uses high-quality sealing materials to securely seal the cans, preventing any leakage or contamination. The sealing process is also automated, ensuring a uniform and secure seal on every can.

Once the cans are sealed, they are then moved to the labeling machine. This machine automatically applies labels to the cans, providing essential information such as the product name, ingredients, manufacturing date, and expiry date. The labeling machine is designed to apply labels accurately and consistently, enhancing the overall appearance of the product and ensuring compliance with labeling regulations.

The final stage in the automatic powder tin can packing line is the packing machine. This machine packs the cans into boxes or cartons for easy transportation and storage. The packing machine is capable of packing multiple cans at a time, significantly increasing the speed of the packing process.

One of the key advantages of the automatic powder tin can packing line is its high efficiency. By automating the entire packing process, it eliminates the need for manual labor, reducing the risk of errors and inconsistencies. The machines in the packing line are designed to work at high speeds, significantly increasing the production capacity.

Moreover, the automatic powder tin can packing line ensures precision in every stage of the packing process. The filling machine accurately measures the powder, the sealing machine ensures a secure seal, the labeling machine applies labels accurately, and the packing machine packs the cans efficiently. This precision not only enhances the quality of the product but also reduces wastage, further increasing efficiency.

The automatic powder tin can packing line is also highly flexible. It can be easily adjusted to accommodate different sizes and shapes of cans, making it suitable for a wide range of products. This flexibility allows manufacturers to use the same packing line for different products, reducing the need for multiple packing lines and saving space and resources.

In conclusion, the automatic powder tin can packing line is a highly efficient and effective solution for packing powder into tin cans. Its high speed, precision, and flexibility make it an ideal choice for manufacturers looking to enhance their productivity and efficiency. By automating the entire packing process, it not only reduces manual labor but also ensures consistency and quality in every can. As technology continues to advance, we can expect to see even more improvements and innovations in the automatic powder tin can packing line, further enhancing its efficiency and effectiveness.

Innovations in Automatic Powder Tin Can Packing Line: A Comprehensive Review

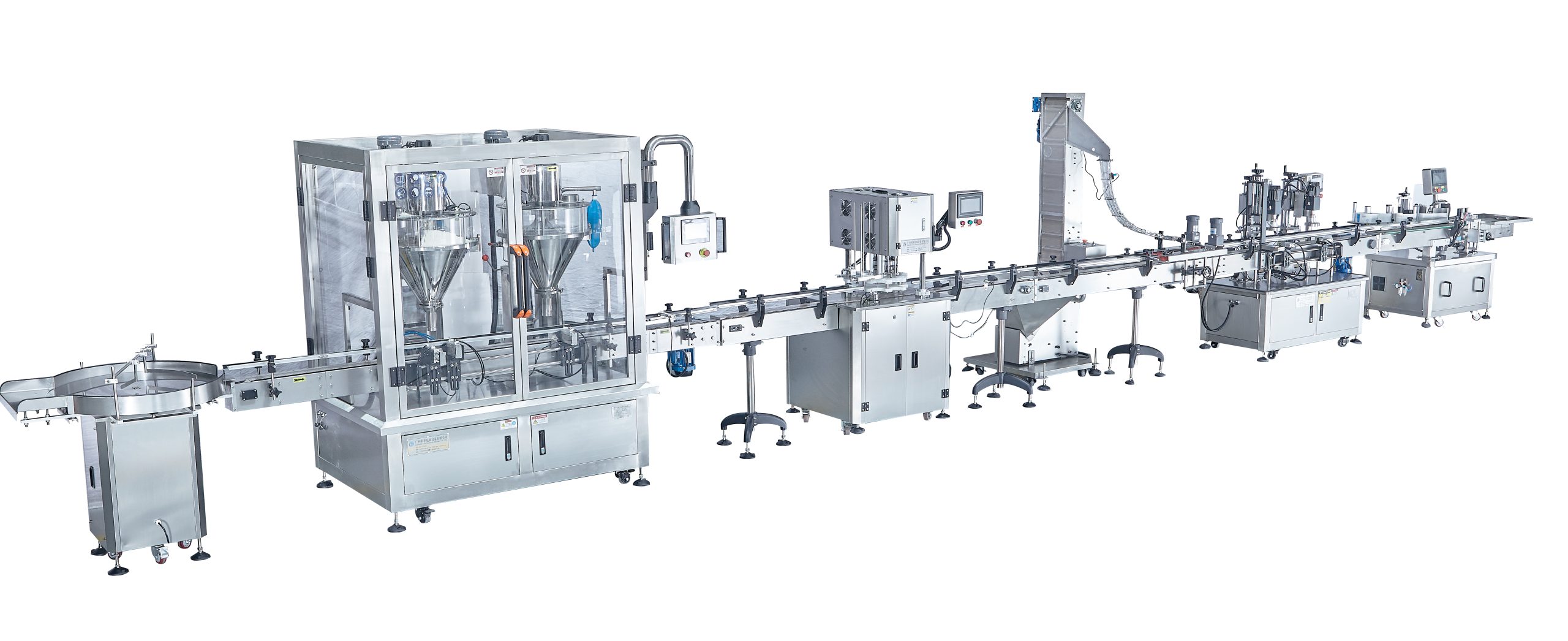

The automatic powder tin can packing line is a remarkable innovation in the packaging industry, revolutionizing the way products are packed and distributed. This advanced technology has significantly improved efficiency, accuracy, and speed in the packaging process, thereby enhancing productivity and reducing operational costs.

The automatic powder tin can packing line is a comprehensive system that integrates various processes such as filling, sealing, and labeling into a single, streamlined operation. This integration eliminates the need for manual intervention, thereby reducing the risk of human error and ensuring consistent product quality. The system is designed to handle a wide range of powder products, including food items, pharmaceuticals, and industrial chemicals, making it a versatile solution for diverse industries.

One of the key innovations in the automatic powder tin can packing line is the precision filling system. This system uses advanced sensors and control algorithms to accurately measure the quantity of powder to be filled into each tin can. The precision filling system ensures that each can is filled to the exact specified level, thereby eliminating wastage and ensuring consistent product quality. This is particularly important for industries such as pharmaceuticals, where precise dosage is critical.

Another significant innovation is the high-speed sealing system. This system uses state-of-the-art technology to securely seal each tin can at a rapid pace, thereby increasing the production rate. The high-speed sealing system also ensures that each can is sealed tightly, preventing leakage and contamination, and preserving the quality of the product.

The automatic labeling system is another noteworthy innovation. This system uses advanced image recognition technology to accurately position and apply labels on each tin can. The automatic labeling system not only speeds up the labeling process but also ensures that each label is applied correctly and consistently, enhancing the aesthetic appeal of the product and ensuring compliance with labeling regulations.

The automatic powder tin can packing line also incorporates advanced monitoring and control systems. These systems continuously monitor the operation of the packing line, detecting any anomalies or faults and initiating corrective actions. The monitoring and control systems also provide real-time data on the performance of the packing line, enabling operators to optimize the operation and maintain peak performance.

The automatic powder tin can packing line is also designed with sustainability in mind. The system minimizes waste by accurately measuring and controlling the quantity of powder used in each can. Moreover, the system is energy-efficient, reducing the environmental impact of the packaging process.

In conclusion, the automatic powder tin can packing line is a game-changer in the packaging industry. Its innovative features such as precision filling, high-speed sealing, automatic labeling, and advanced monitoring and control systems, not only enhance efficiency and productivity but also ensure consistent product quality and compliance with regulations. Moreover, its focus on sustainability makes it a responsible choice for the environment. As the demand for efficient and sustainable packaging solutions continues to grow, the automatic powder tin can packing line is set to play a pivotal role in meeting this demand.