Benefits of Using an Automatic Liquid Product Filling and Vacuum Seaming Machine Line

Automatic liquid product filling and vacuum seaming machine lines have revolutionized the packaging industry by providing a fast, efficient, and reliable solution for filling and sealing liquid products. These machines are designed to handle a wide range of liquid products, including beverages, sauces, oils, and more. By automating the filling and sealing process, businesses can increase productivity, reduce labor costs, and improve overall product quality.

One of the key benefits of using an automatic liquid product filling and vacuum seaming machine line is the speed at which it can fill and seal products. These machines are capable of filling and sealing hundreds of containers per minute, significantly faster than manual filling and sealing methods. This increased speed allows businesses to meet high production demands and fulfill orders quickly and efficiently.

In addition to speed, automatic liquid product filling and vacuum seaming machine lines also offer a high level of accuracy and consistency. These machines are equipped with precision filling mechanisms that ensure each container is filled with the exact amount of product, eliminating waste and ensuring product quality. The vacuum seaming process also ensures a tight seal on each container, preventing leaks and preserving product freshness.

Another benefit of using an automatic liquid product filling and vacuum seaming machine line is the reduction in labor costs. By automating the filling and sealing process, businesses can significantly reduce the need for manual labor, saving time and money. This allows businesses to reallocate resources to other areas of the production process, increasing overall efficiency and profitability.

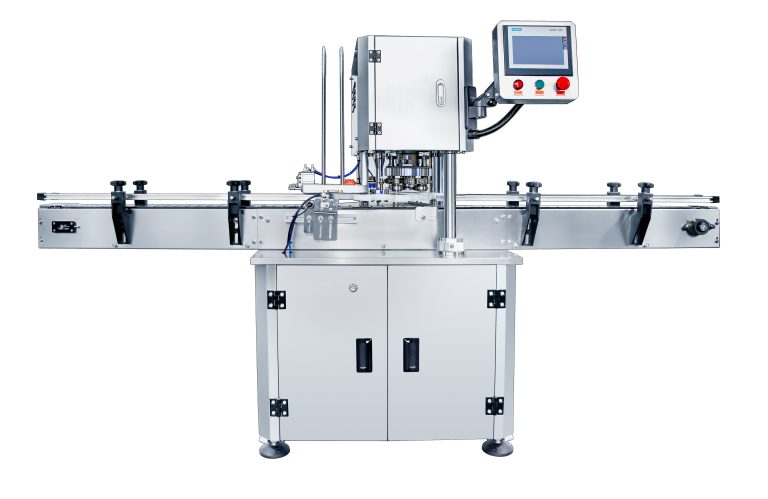

Furthermore, automatic liquid product filling and vacuum seaming machine lines are easy to operate and require minimal maintenance. These machines are designed with user-friendly interfaces and intuitive controls, making them accessible to operators of all skill levels. Additionally, the durable construction of these machines ensures long-term reliability and minimal downtime, maximizing productivity and reducing production interruptions.

In addition to the operational benefits, automatic liquid product filling and vacuum seaming machine lines also offer a range of customization options to meet the specific needs of each business. These machines can be tailored to accommodate different container sizes, product viscosities, and production volumes, ensuring a seamless integration into existing production lines. This flexibility allows businesses to optimize their production processes and adapt to changing market demands.

Overall, the benefits of using an automatic liquid product filling and vacuum seaming machine line are clear. From increased speed and accuracy to reduced labor costs and easy operation, these machines offer a comprehensive solution for businesses looking to streamline their packaging processes and improve overall efficiency. By investing in an automatic liquid product filling and vacuum seaming machine line, businesses can enhance their production capabilities, increase profitability, and stay ahead of the competition in today’s fast-paced market.