Table of Contents

Benefits of Using Automatic Liquid Ghee Oil Bottle Filling Capping Labeling Machine Line

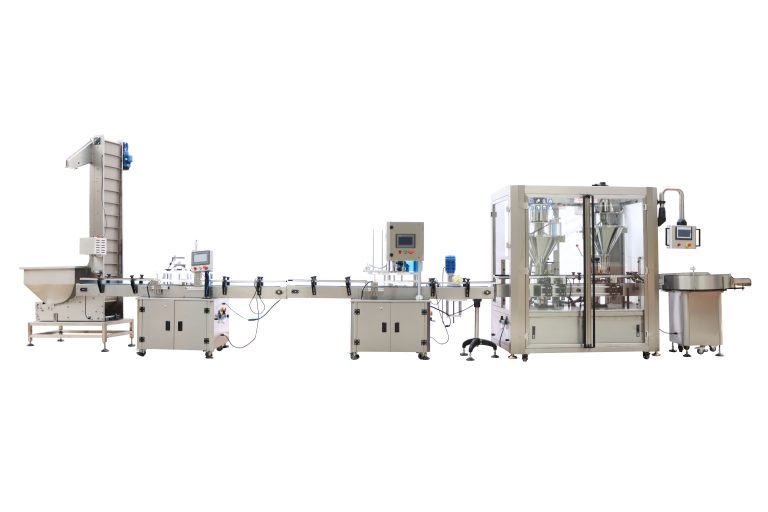

Automatic Liquid Ghee Oil Bottle Filling Capping Labeling Machine Line is a revolutionary technology that has transformed the way liquid ghee oil is packaged and labeled. This advanced machine line offers a wide range of benefits for businesses looking to streamline their production process and improve efficiency.

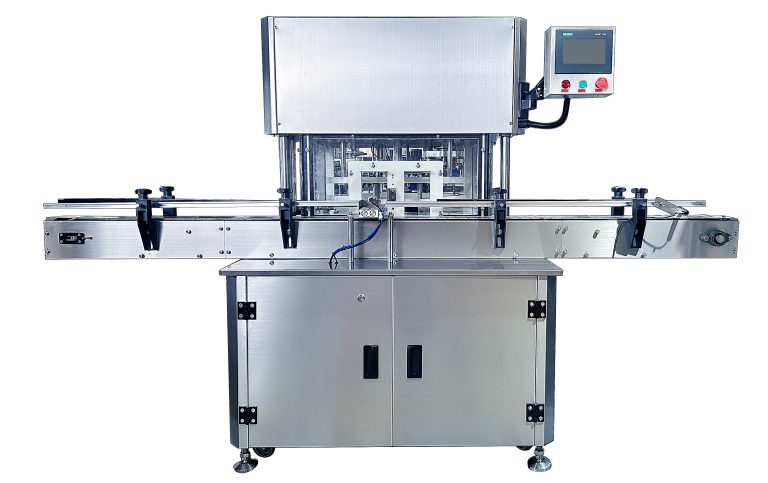

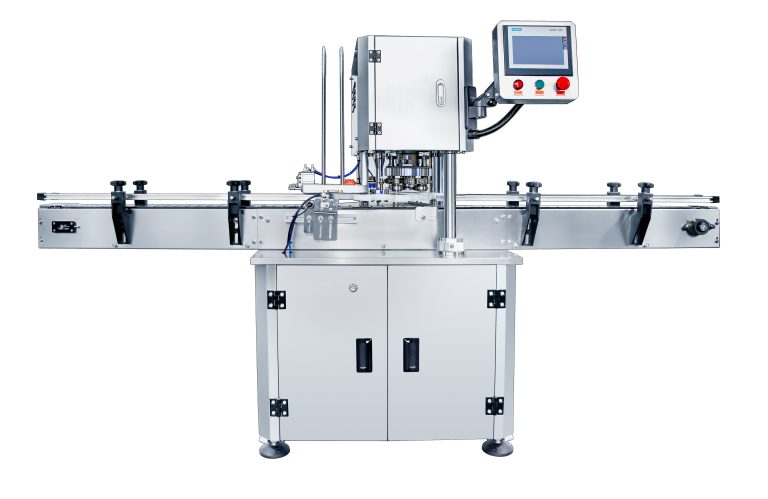

One of the key benefits of using an automatic liquid ghee oil bottle filling capping labeling machine line is the speed and accuracy it offers. These machines are designed to fill, cap, and label bottles at a much faster rate than manual labor, saving businesses valuable time and resources. The precision of these machines ensures that each bottle is filled to the exact measurement, capped securely, and labeled correctly, reducing the risk of errors and waste.

In addition to speed and accuracy, automatic liquid ghee oil bottle filling capping labeling machine lines also offer increased efficiency. By automating the packaging and labeling process, businesses can significantly reduce the amount of labor required to complete these tasks. This not only saves time but also allows employees to focus on other important aspects of the production process, improving overall productivity.

Another benefit of using an automatic liquid ghee oil bottle filling capping labeling machine line is the consistency it provides. These machines are programmed to perform the same tasks repeatedly, ensuring that each bottle is filled, capped, and labeled in the same manner. This consistency is crucial for maintaining product quality and meeting customer expectations, ultimately leading to increased customer satisfaction and loyalty.

Furthermore, automatic liquid ghee oil bottle filling capping labeling machine lines are highly versatile and can be customized to meet the specific needs of different businesses. Whether a business is packaging liquid ghee oil in different bottle sizes or shapes, these machines can be adjusted to accommodate various packaging requirements. This flexibility allows businesses to adapt to changing market demands and stay ahead of the competition.

In addition to the benefits mentioned above, using an automatic liquid ghee oil bottle filling capping labeling machine line can also lead to cost savings for businesses. By reducing the amount of labor required for packaging and labeling, businesses can lower their production costs and improve their bottom line. Additionally, the efficiency and accuracy of these machines can help minimize waste and reduce the risk of product recalls, further saving businesses money in the long run.

Overall, the benefits of using an automatic liquid ghee oil bottle filling capping labeling machine line are clear. From increased speed and accuracy to improved efficiency and cost savings, these machines offer a wide range of advantages for businesses looking to streamline their production process and enhance their overall operations. By investing in this advanced technology, businesses can stay competitive in the market and meet the growing demands of their customers.

How to Choose the Right Automatic Liquid Ghee Oil Bottle Filling Capping Labeling Machine Line for Your Business

When it comes to packaging liquid ghee oil in bottles, having the right equipment is essential to ensure efficiency and accuracy in the production process. An automatic liquid ghee oil bottle filling capping labeling machine line can streamline the packaging process and increase productivity. However, with so many options available on the market, choosing the right machine line for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting an automatic liquid ghee oil bottle filling capping labeling machine line.

First and foremost, it is important to consider the production capacity of the machine line. The capacity of the machine line should align with the volume of liquid ghee oil that your business produces on a daily basis. It is essential to choose a machine line that can handle the volume of production without causing any bottlenecks in the packaging process. Additionally, consider the speed at which the machine line can fill, cap, and label the bottles to ensure that it meets the demands of your business.

Another important factor to consider is the accuracy and precision of the machine line. The machine line should be able to fill each bottle with the correct amount of liquid ghee oil, cap the bottles securely, and apply labels accurately. This will help to minimize wastage and ensure that each bottle meets the quality standards of your business. Look for a machine line that is equipped with sensors and controls to ensure precise filling, capping, and labeling of the bottles.

In addition to capacity and accuracy, it is also important to consider the flexibility of the machine line. Your business may need to package liquid ghee oil in different bottle sizes and shapes, so it is important to choose a machine line that can accommodate various bottle sizes and shapes. Look for a machine line that is adjustable and can be easily configured to handle different bottle sizes and shapes. This will allow your business to adapt to changing packaging requirements and expand its product offerings.

Furthermore, consider the ease of maintenance and operation of the machine line. The machine line should be easy to clean and maintain to ensure smooth operation and prevent downtime. Look for a machine line that is user-friendly and comes with clear instructions for operation and maintenance. Additionally, consider the availability of spare parts and technical support to ensure that any issues with the machine line can be quickly resolved.

Lastly, consider the cost of the machine line and the return on investment it will provide for your business. While it is important to choose a machine line that meets the needs of your business, it is also important to consider the cost implications. Compare the prices of different machine lines and consider the long-term benefits and savings that each machine line can provide. Choose a machine line that offers the best value for money and will help your business achieve its production goals efficiently.

In conclusion, choosing the right automatic liquid ghee oil bottle filling capping labeling machine line for your business requires careful consideration of factors such as production capacity, accuracy, flexibility, ease of maintenance and operation, and cost. By taking these factors into account, you can select a machine line that will streamline the packaging process, increase productivity, and ultimately contribute to the success of your business.