Table of Contents

Benefits of Using an Automatic Linear Screw Bottle Servo Capping Machine

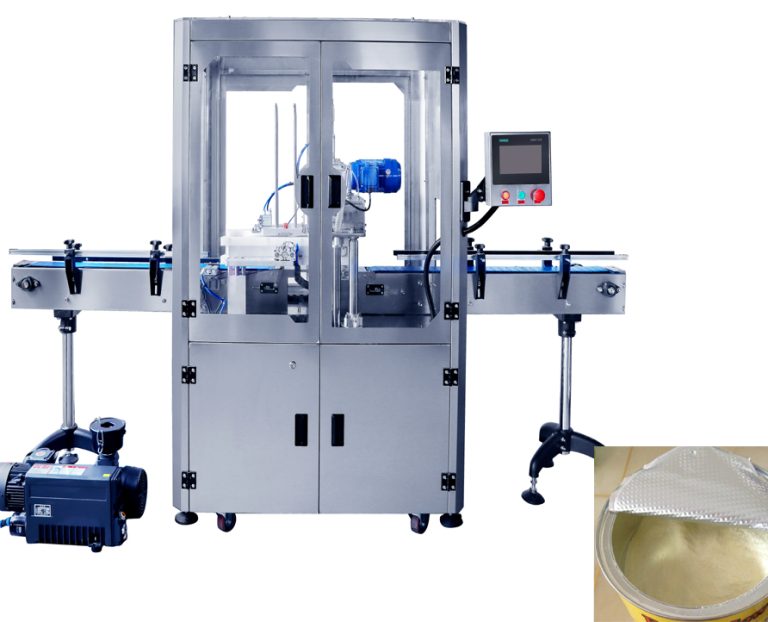

An automatic linear screw bottle servo capping machine with a cap elevator is a valuable piece of equipment for businesses in the packaging industry. This machine offers numerous benefits that can streamline the capping process and improve overall efficiency.

One of the key advantages of using an automatic linear screw bottle servo capping machine is its ability to cap bottles quickly and accurately. The servo-driven technology ensures precise torque control, resulting in consistent and secure bottle closures. This is essential for maintaining product quality and preventing leaks or contamination. Additionally, the automatic operation of the machine reduces the need for manual labor, saving time and labor costs for businesses.

Another benefit of the automatic linear screw bottle servo capping machine is its versatility. This machine is capable of capping a wide range of bottle sizes and shapes, making it suitable for various packaging applications. Whether you are capping bottles of different heights or diameters, this machine can easily adjust to accommodate your specific needs. This flexibility allows businesses to streamline their capping process and improve overall production efficiency.

In addition to its speed and versatility, the automatic linear screw bottle servo capping machine offers a high level of reliability. The servo-driven technology ensures consistent performance, reducing the risk of downtime or malfunctions. This reliability is crucial for businesses that rely on continuous production to meet customer demands and deadlines. By investing in a reliable capping machine, businesses can minimize disruptions and maintain a smooth production flow.

Furthermore, the automatic linear screw bottle servo capping machine is designed for ease of use and maintenance. The user-friendly interface allows operators to easily set up and adjust the machine for different bottle sizes and capping requirements. Additionally, the machine is constructed with durable materials that require minimal maintenance, reducing downtime and repair costs. This ease of use and maintenance makes the machine a cost-effective investment for businesses looking to improve their packaging operations.

Overall, the automatic linear screw bottle servo capping machine with a cap elevator offers numerous benefits for businesses in the packaging industry. From its speed and accuracy to its versatility and reliability, this machine can help streamline the capping process and improve overall efficiency. By investing in this advanced capping technology, businesses can enhance their production capabilities and meet the demands of a competitive market.

How to Choose the Right Cap Elevator for Your Capping Machine

When it comes to choosing the right cap elevator for your capping machine, there are several factors to consider in order to ensure optimal performance and efficiency. One of the key components of a capping machine is the cap elevator, which is responsible for feeding caps to the capping head in a consistent and reliable manner. In this article, we will discuss the importance of selecting the right cap elevator for your capping machine and provide some tips on how to make the best choice.

First and foremost, it is important to consider the size and shape of the caps that will be used with the capping machine. Different cap elevators are designed to handle different types of caps, so it is essential to choose one that is compatible with the caps you will be using. Additionally, the speed at which the caps need to be fed to the capping head should also be taken into account when selecting a cap elevator. Some cap elevators are capable of handling higher speeds than others, so it is important to choose one that can keep up with the production requirements of your capping machine.

Another important factor to consider when choosing a cap elevator is the overall design and construction of the machine. The cap elevator should be durable and reliable, as it will be subjected to constant use and wear and tear. It is also important to choose a cap elevator that is easy to clean and maintain, as this will help to prolong its lifespan and ensure consistent performance over time.

In addition to considering the size, speed, and design of the cap elevator, it is also important to think about the overall compatibility of the cap elevator with the capping machine. Some cap elevators are specifically designed to work with certain types of capping machines, so it is important to choose one that is compatible with the make and model of your capping machine. This will help to ensure seamless integration and optimal performance when the cap elevator is installed and put into use.

When choosing a cap elevator for your capping machine, it is also important to consider the level of automation that is desired. Some cap elevators are fully automatic and require minimal human intervention, while others may require more manual operation. The level of automation that is best for your capping machine will depend on factors such as production volume, available space, and budget constraints.

In conclusion, choosing the right cap elevator for your capping machine is essential for ensuring optimal performance and efficiency. By considering factors such as cap size, speed, design, compatibility, and automation level, you can make an informed decision that will help to maximize the productivity of your capping machine. With the right cap elevator in place, you can streamline your capping process and achieve consistent, reliable results with every bottle that passes through the machine.