Table of Contents

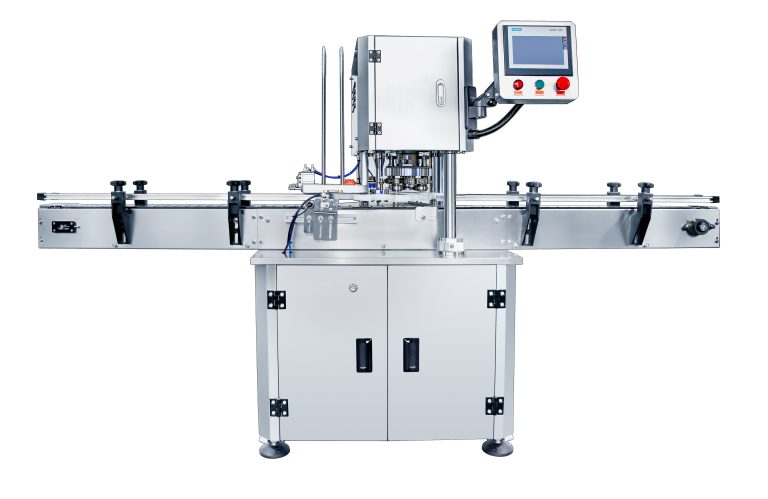

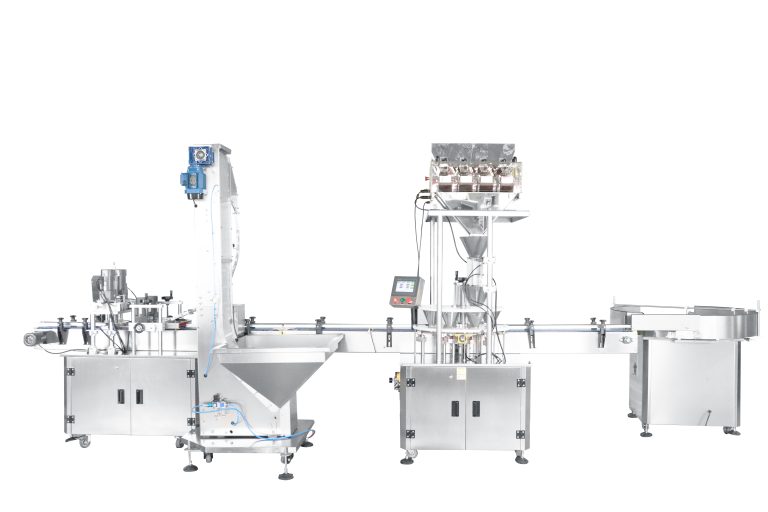

Increased Efficiency in Snack Food Packaging with Automatic Dual Head Tin Can Closing Machine

In the fast-paced world of snack food production, efficiency is key. Manufacturers are constantly looking for ways to streamline their processes and increase output without sacrificing quality. One area where significant improvements can be made is in the packaging stage. Tin cans are a popular choice for packaging snack foods due to their durability and ability to preserve freshness. However, manually sealing tin cans can be a time-consuming and labor-intensive process. This is where automatic dual head tin can closing machines come in.

These machines are designed to automatically seal tin cans with precision and speed, eliminating the need for manual labor and reducing the risk of human error. The dual head design allows for two cans to be sealed simultaneously, further increasing efficiency. This means that snack food manufacturers can seal more cans in less time, ultimately increasing their output and profitability.

One of the key benefits of automatic dual head tin can closing machines is their consistency. Manual sealing can vary in quality depending on the skill and experience of the operator. With automatic machines, each can is sealed with the same level of precision every time, ensuring a uniform and professional finish. This is particularly important in the snack food industry, where presentation plays a crucial role in consumer perception.

Another advantage of these machines is their speed. Manual sealing can be a slow and tedious process, especially when dealing with large volumes of cans. Automatic machines can seal cans in a fraction of the time it would take a human operator, allowing manufacturers to meet tight production deadlines and keep up with demand.

In addition to efficiency and consistency, automatic dual head tin can closing machines also offer cost savings. While the initial investment in a machine may be significant, the long-term savings in labor costs and increased productivity can quickly offset this expense. Furthermore, the reduced risk of errors and rework can lead to further savings in the form of reduced waste and improved overall efficiency.

Overall, automatic dual head tin can closing machines are a valuable asset for snack food manufacturers looking to increase efficiency and streamline their packaging processes. By automating the sealing process, these machines can help companies meet production targets, improve product quality, and reduce costs. With the snack food industry becoming increasingly competitive, investing in automation technology is essential for staying ahead of the curve.

In conclusion, automatic dual head tin can closing machines offer a range of benefits for snack food manufacturers looking to improve their packaging processes. From increased efficiency and consistency to cost savings and improved productivity, these machines are a valuable investment for companies looking to stay competitive in the fast-paced snack food industry. By embracing automation technology, manufacturers can streamline their operations, increase output, and ultimately deliver a better product to consumers.

Ensuring Product Freshness and Seal Integrity with Automatic Dual Head Tin Can Closing Machine

In the snack food industry, ensuring product freshness and seal integrity is crucial to maintaining customer satisfaction and loyalty. One way to achieve this is through the use of an automatic dual head tin can closing machine. This innovative piece of equipment is designed to efficiently seal tin cans, keeping the contents fresh and secure.

The automatic dual head tin can closing machine is a versatile and reliable solution for snack food manufacturers looking to streamline their production process. With two closing heads, this machine can handle a high volume of cans, increasing productivity and reducing the risk of human error. The dual head design also allows for different closure types to be used simultaneously, providing flexibility for manufacturers with diverse product lines.

One of the key benefits of the automatic dual head tin can closing machine is its ability to ensure a consistent and tight seal on every can. This is essential for preserving the freshness of snack foods and preventing contamination. By automating the closing process, manufacturers can eliminate variations in seal quality that can occur with manual sealing methods, resulting in a more reliable product for consumers.

In addition to maintaining product freshness, the automatic dual head tin can closing machine also helps to extend the shelf life of snack foods. By creating a secure seal, this machine prevents air and moisture from entering the can, which can lead to spoilage and degradation of the product. This not only reduces waste and improves product quality but also enhances the overall customer experience.

Furthermore, the automatic dual head tin can closing machine is designed to be user-friendly and easy to operate. With intuitive controls and a simple setup process, manufacturers can quickly integrate this machine into their production line without extensive training or technical expertise. This allows for a seamless transition to automated can closing, saving time and resources for the manufacturer.

Another advantage of the automatic dual head tin can closing machine is its durability and reliability. Built with high-quality materials and precision engineering, this machine is designed to withstand the rigors of continuous use in a production environment. This ensures consistent performance and minimal downtime, maximizing efficiency and productivity for snack food manufacturers.

Overall, the automatic dual head tin can closing machine is a valuable investment for snack food manufacturers looking to enhance product freshness and seal integrity. By automating the can closing process, this machine helps to maintain the quality and safety of snack foods while improving production efficiency and reducing waste. With its user-friendly design and reliable performance, the automatic dual head tin can closing machine is a versatile solution for manufacturers seeking to optimize their production process and deliver high-quality products to consumers.

Streamlining Production Processes in Snack Food Industry with Automatic Dual Head Tin Can Closing Machine

In the fast-paced world of snack food production, efficiency is key. Manufacturers are constantly looking for ways to streamline their processes and increase output without sacrificing quality. One innovative solution that has been gaining popularity in recent years is the automatic dual head tin can closing machine.

This machine is specifically designed to streamline the closing process for tin cans used in snack food packaging. By automating this step, manufacturers can significantly increase their production capacity while reducing the risk of errors and inconsistencies.

The automatic dual head tin can closing machine is equipped with two closing heads, allowing it to close two cans simultaneously. This not only speeds up the process but also ensures that each can is sealed properly and securely. This is especially important in the snack food industry, where freshness and quality are paramount.

One of the key benefits of this machine is its versatility. It can be easily adjusted to accommodate different can sizes, making it suitable for a wide range of snack food products. This flexibility allows manufacturers to quickly switch between different packaging options without the need for extensive retooling or downtime.

Another advantage of the automatic dual head tin can closing machine is its user-friendly design. Operators can easily set up and operate the machine with minimal training, reducing the risk of human error and increasing overall efficiency. This is particularly important in high-volume production environments where speed and accuracy are essential.

In addition to improving efficiency, the automatic dual head tin can closing machine also helps to ensure product quality. By sealing cans quickly and securely, manufacturers can prevent contamination and spoilage, ultimately extending the shelf life of their products. This is crucial in the snack food industry, where freshness is a key selling point for consumers.

Furthermore, the automatic dual head tin can closing machine can help manufacturers meet strict regulatory requirements. By consistently sealing cans to industry standards, manufacturers can avoid costly fines and recalls, protecting both their bottom line and their reputation.

Overall, the automatic dual head tin can closing machine is a valuable tool for streamlining production processes in the snack food industry. Its ability to increase efficiency, ensure product quality, and meet regulatory requirements make it an essential investment for manufacturers looking to stay competitive in today’s fast-paced market.

In conclusion, the automatic dual head tin can closing machine is a game-changer for snack food manufacturers looking to streamline their production processes. Its speed, versatility, user-friendly design, and quality assurance capabilities make it a valuable asset for any company looking to increase efficiency and output without sacrificing quality. By investing in this innovative technology, manufacturers can stay ahead of the competition and meet the growing demands of today’s snack food market.