Exploring the Efficiency of Automatic Canned Meat, Beef, Sardine Can Packaging Line

The automatic canned meat, beef, and sardine can packaging line is a marvel of modern technology that has revolutionized the food processing industry. This innovative system has significantly improved the efficiency of food packaging, ensuring that products reach consumers in the best possible condition. The automatic packaging line is a testament to the power of automation and its potential to transform industries.

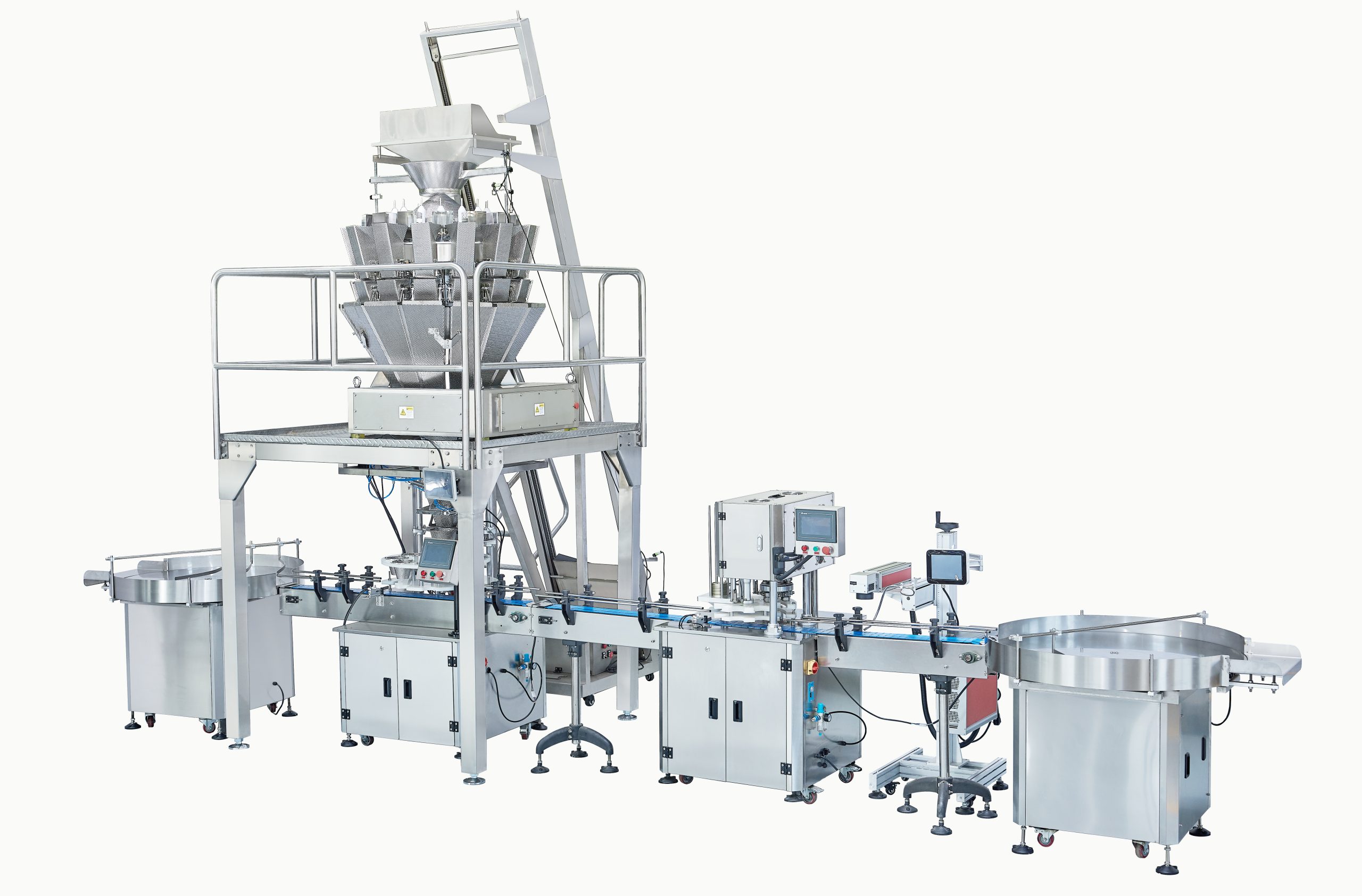

The automatic canned meat, beef, and sardine can packaging line is a complex system that integrates various processes into a seamless operation. It begins with the preparation of the meat, which is cleaned, cut, and cooked to perfection. The meat is then transferred to the canning section, where it is carefully placed into cans. The cans are then sealed to ensure that the meat remains fresh and safe for consumption.

The sealing process is particularly crucial as it prevents the entry of air and bacteria, which could compromise the quality of the meat. The cans are then labeled and packed into boxes, ready for distribution. This entire process is automated, which eliminates the need for manual labor and significantly reduces the chances of human error.

One of the key benefits of the automatic canned meat, beef, and sardine can packaging line is its speed. The system can process thousands of cans per hour, which is far more than what could be achieved manually. This high-speed operation ensures that large volumes of meat can be processed and packaged in a short period, thereby meeting the high demand for these products.

Moreover, the automatic packaging line is highly accurate. The system is designed to ensure that each can contains the exact amount of meat, which is crucial for maintaining consistency and meeting regulatory standards. The precision of the automatic packaging line also reduces wastage, as there is less likelihood of overfilling or underfilling the cans.

Another advantage of the automatic canned meat, beef, and sardine can packaging line is its reliability. The system is designed to operate continuously without breakdowns, ensuring that the production process is not disrupted. This reliability is crucial in the food processing industry, where any delay could lead to spoilage and loss of revenue.

The automatic canned meat, beef, and sardine can packaging line also contributes to improved hygiene. Since the process is automated, there is minimal human contact with the meat, which reduces the risk of contamination. The system is also easy to clean and maintain, which further enhances its hygiene standards.

In conclusion, the automatic canned meat, beef, and sardine can packaging line is a game-changer in the food processing industry. Its speed, accuracy, reliability, and hygiene standards have significantly improved the efficiency of food packaging. As technology continues to advance, we can expect even more improvements in this area, further enhancing the quality and safety of our food.