Table of Contents

Benefits of Using Automatic Can Lid Covers Capping Machine

Automatic can lid covers capping machines have revolutionized the packaging industry by providing a fast and efficient way to seal tin cans. These machines offer a wide range of benefits that make them a valuable investment for businesses looking to streamline their production processes and improve overall efficiency.

One of the key benefits of using an automatic can lid covers capping machine is the speed at which it can cap cans. These machines are capable of capping hundreds of cans per minute, significantly reducing the time and labor required to seal cans manually. This increased speed not only improves productivity but also allows businesses to meet tight production deadlines and fulfill customer orders in a timely manner.

In addition to speed, automatic can lid covers capping machines also offer a high level of accuracy and consistency in the capping process. These machines are equipped with advanced technology that ensures each can is sealed with precision, eliminating the risk of leaks or contamination. This level of consistency is crucial for businesses operating in industries where product quality and safety are top priorities.

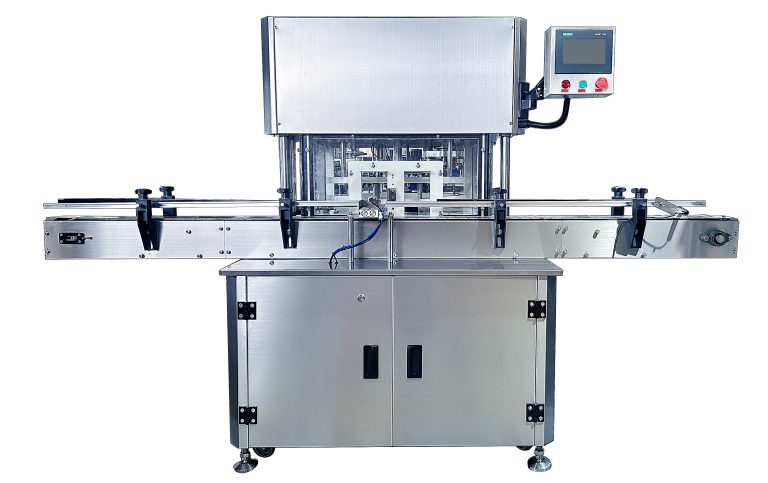

Furthermore, automatic can lid covers capping machines are designed to be user-friendly and easy to operate. With intuitive controls and minimal setup requirements, these machines can be quickly integrated into existing production lines without the need for extensive training or technical expertise. This ease of use not only saves time but also reduces the likelihood of human error, resulting in a more reliable and efficient capping process.

Another significant benefit of using automatic can lid covers capping machines is the reduction in waste and product loss. By sealing cans with precision and accuracy, these machines minimize the risk of spills or leaks during the capping process, ensuring that every can is properly sealed and ready for distribution. This not only helps businesses save money on wasted product but also improves overall product quality and customer satisfaction.

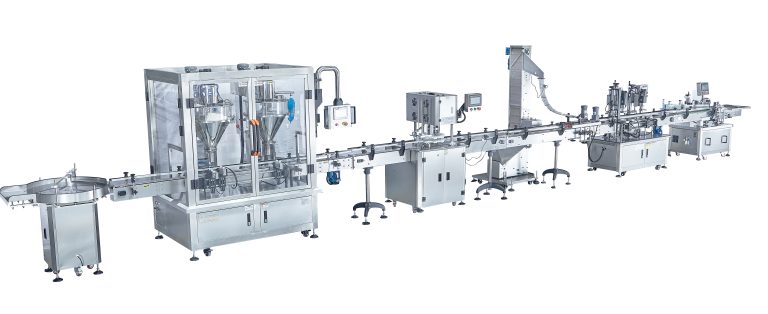

Additionally, automatic can lid covers capping machines are highly versatile and can be customized to meet the specific needs of different industries and products. Whether sealing cans of food, beverages, or chemicals, these machines can be adjusted to accommodate various can sizes and lid types, making them a versatile solution for businesses with diverse product lines.

Overall, the benefits of using automatic can lid covers capping machines are clear. From increased speed and accuracy to reduced waste and improved product quality, these machines offer a range of advantages that can help businesses streamline their production processes and achieve greater efficiency. By investing in an automatic can lid covers capping machine, businesses can not only save time and money but also enhance their overall competitiveness in the market.

How to Choose the Right Automatic Can Lid Covers Capping Machine for Your Needs

Automatic can lid covers capping machines are essential equipment for businesses that deal with a high volume of tin cans. These machines are designed to efficiently seal cans with lids, ensuring that the contents remain fresh and protected from external contaminants. When choosing the right automatic can lid covers capping machine for your needs, there are several factors to consider to ensure that you select the best option for your business.

One of the most important factors to consider when choosing an automatic can lid covers capping machine is the speed and efficiency of the machine. Different machines have varying capacities and speeds, so it is essential to assess your production needs to determine the appropriate machine for your business. If you have a high volume of cans that need to be sealed quickly, you will need a machine that can handle the workload efficiently.

Another crucial factor to consider is the size and type of cans that the machine can accommodate. Automatic can lid covers capping machines come in various sizes and configurations, so it is essential to choose a machine that can seal the cans you use in your business. Some machines are designed for specific can sizes, while others are adjustable to accommodate different sizes. Make sure to choose a machine that can handle the cans you use to avoid any compatibility issues.

Additionally, consider the level of automation and customization that the machine offers. Some automatic can lid covers capping machines come with advanced features such as automatic lid feeding, lid detection, and adjustable sealing pressure. These features can help streamline the sealing process and ensure consistent results. If you require a high level of customization or automation, look for a machine that offers these features to meet your specific needs.

When choosing an automatic can lid covers capping machine, it is also essential to consider the maintenance and support services provided by the manufacturer. Look for a reputable manufacturer that offers reliable customer support and maintenance services to ensure that your machine operates smoothly and efficiently. Regular maintenance is crucial to prolonging the lifespan of the machine and preventing breakdowns that can disrupt your production process.

In conclusion, choosing the right automatic can lid covers capping machine for your business requires careful consideration of several factors. Assess your production needs, the size and type of cans you use, and the level of automation and customization required to select the best machine for your business. Additionally, consider the maintenance and support services provided by the manufacturer to ensure that your machine operates smoothly and efficiently. By taking these factors into account, you can choose a reliable and efficient automatic can lid covers capping machine that meets your business needs.

Maintenance Tips for Automatic Can Lid Covers Capping Machine

Automatic can lid covers capping machines are essential equipment in the food and beverage industry. These machines are designed to efficiently seal tin cans with lids, ensuring the product inside remains fresh and safe for consumption. To ensure the smooth operation of your automatic can lid covers capping machine, it is important to follow proper maintenance procedures. In this article, we will discuss some maintenance tips to help you keep your machine in top condition.

Regular cleaning is essential to prevent the buildup of debris and contaminants that can affect the performance of your automatic can lid covers capping machine. Make sure to clean the machine thoroughly after each use, paying special attention to the capping head and the conveyor belt. Use a mild detergent and a soft brush to remove any residue, and rinse with clean water to ensure all cleaning agents are removed.

Inspect the machine regularly for any signs of wear and tear. Check for loose or damaged parts, such as belts, chains, and gears, and replace them as needed. Lubricate moving parts according to the manufacturer’s recommendations to prevent friction and ensure smooth operation. Proper lubrication will also help extend the life of your machine and reduce the risk of breakdowns.

Calibrate the machine regularly to ensure accurate capping. Over time, the settings on your automatic can lid covers capping machine may drift, leading to improper sealing of cans. Use a torque tester to check the capping force and adjust the settings as needed. This will help maintain the quality of your products and prevent leaks or spoilage.

Keep a record of maintenance and repairs to track the performance of your automatic can lid covers capping machine. Note any issues that arise during operation, as well as the steps taken to address them. This information will help you identify recurring problems and make informed decisions about when to schedule maintenance or replacement of parts.

Train your staff on proper operating procedures and maintenance tasks for the automatic can lid covers capping machine. Make sure they understand how to use the machine safely and efficiently, and provide ongoing training to keep their skills up to date. Encourage them to report any issues or concerns promptly, so they can be addressed before they escalate into larger problems.

In conclusion, proper maintenance is essential to keep your automatic can lid covers capping machine running smoothly and efficiently. By following these tips, you can extend the life of your machine, reduce downtime, and ensure the quality of your products. Remember to clean the machine regularly, inspect for wear and tear, calibrate as needed, keep records of maintenance, and train your staff on proper procedures. With these practices in place, you can maximize the performance of your automatic can lid covers capping machine and maintain the integrity of your products.