Table of Contents

Benefits of Using an Automatic 4 Head Popcorn Filling Can Sealing Line

Popcorn is a beloved snack enjoyed by people of all ages around the world. Whether you prefer it buttered, salted, or flavored with various seasonings, there’s no denying the appeal of this crunchy and satisfying treat. For businesses that produce and package popcorn for sale, having an efficient and reliable filling and sealing line is essential to meet the demands of the market. One popular option for popcorn manufacturers is the automatic 4 head popcorn filling can sealing line.

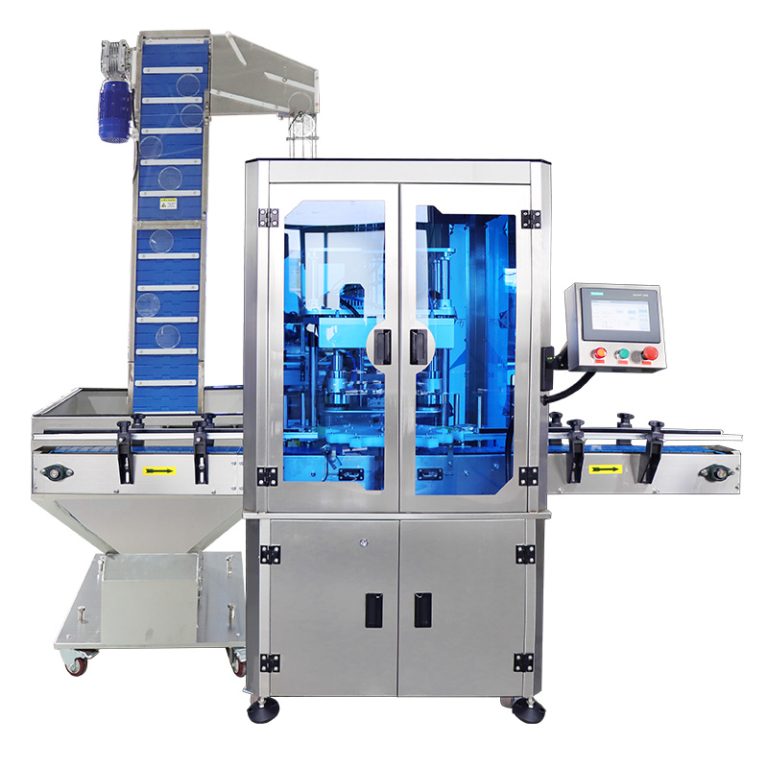

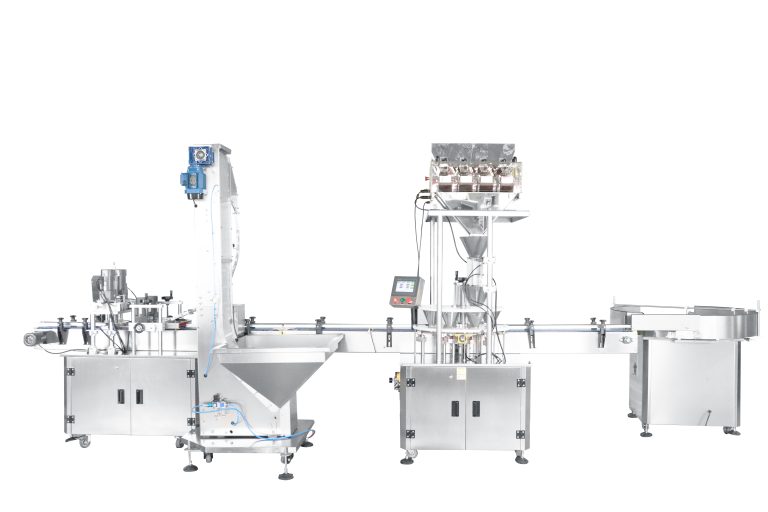

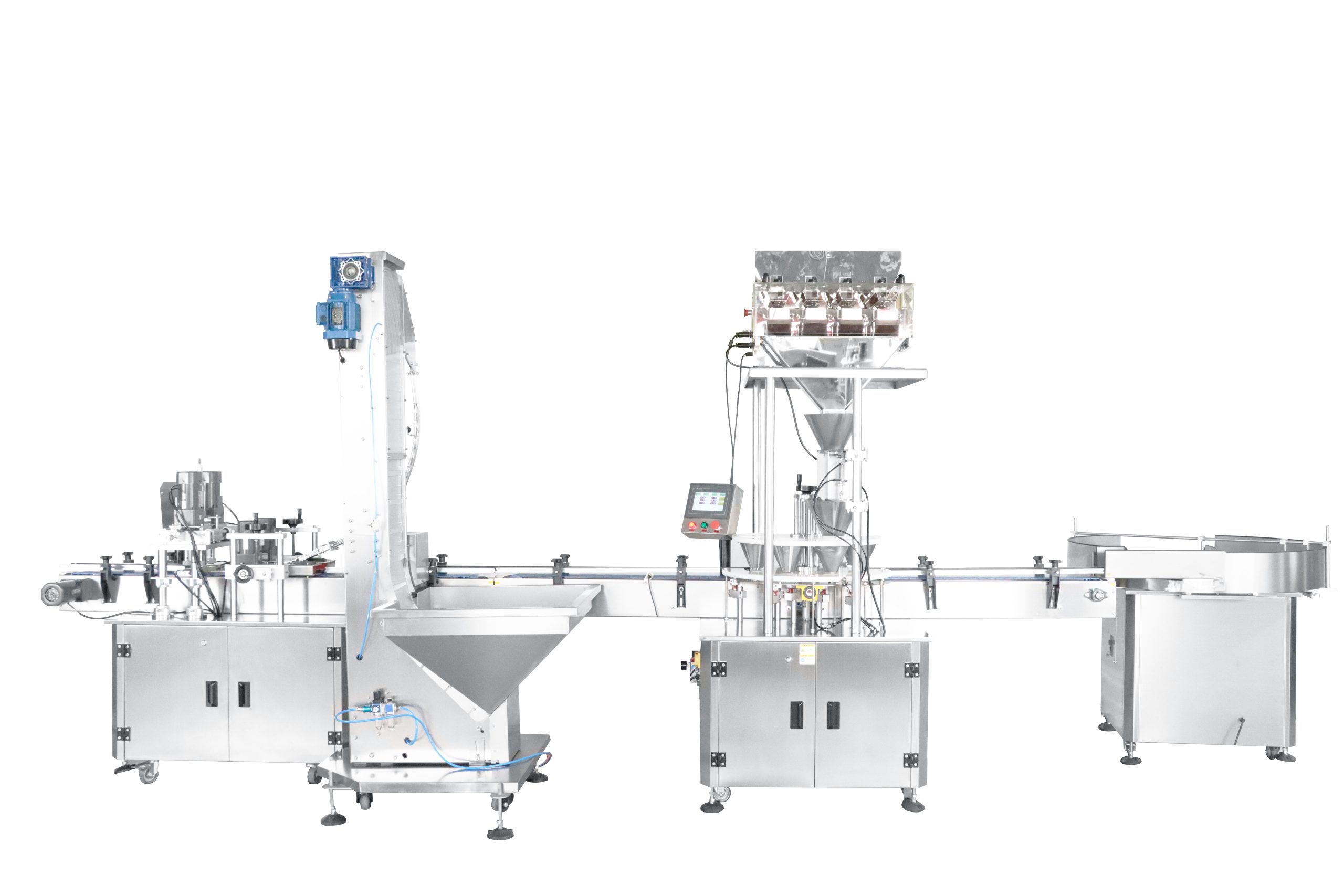

This advanced packaging system offers a range of benefits that can help streamline production processes and improve overall efficiency. One of the key advantages of using an automatic 4 head popcorn filling can sealing line is its ability to fill and seal multiple cans simultaneously. This means that operators can fill four cans at once, significantly increasing the speed and output of the packaging line. This can be especially beneficial for businesses that have high production volumes and need to package large quantities of popcorn quickly and efficiently.

In addition to its speed and efficiency, an automatic 4 head popcorn filling can sealing line also offers a high level of accuracy and consistency. The system is designed to precisely measure and dispense the correct amount of popcorn into each can, ensuring that every package is filled to the same level. This helps to maintain product quality and consistency, which is important for building customer trust and loyalty.

Another benefit of using an automatic 4 head popcorn filling can sealing line is its versatility. This packaging system can be easily adjusted to accommodate different can sizes and fill volumes, making it suitable for a wide range of packaging requirements. Whether you’re packaging small snack-sized cans or larger family-sized containers, this system can be customized to meet your specific needs.

Furthermore, an automatic 4 head popcorn filling can sealing line is designed to be user-friendly and easy to operate. The system is equipped with intuitive controls and features that make it simple for operators to set up and run the packaging line. This can help to reduce training time and minimize the risk of errors or downtime during production.

In addition to its operational benefits, using an automatic 4 head popcorn filling can sealing line can also help to improve overall product quality and shelf life. The system is designed to create a tight and secure seal on each can, which helps to protect the popcorn from moisture, air, and other contaminants that can affect its freshness and flavor. This can help to extend the shelf life of the product and ensure that it reaches consumers in optimal condition.

Overall, the automatic 4 head popcorn filling can sealing line offers a range of benefits for businesses that produce and package popcorn. From increased speed and efficiency to improved accuracy and consistency, this advanced packaging system can help to streamline production processes and enhance product quality. If you’re looking to take your popcorn packaging to the next level, investing in an automatic 4 head filling can sealing line could be a smart choice.

How to Choose the Right Automatic 4 Head Popcorn Filling Can Sealing Line for Your Business

When it comes to choosing the right automatic 4 head popcorn filling can sealing line for your business, there are several factors to consider. This type of equipment is essential for efficiently packaging popcorn in cans, ensuring that the product is sealed properly and ready for distribution. In this article, we will discuss some key considerations to keep in mind when selecting an automatic 4 head popcorn filling can sealing line for your business.

One of the first things to consider when choosing a popcorn filling can sealing line is the production capacity of the equipment. You will need to determine how many cans of popcorn you need to fill and seal per hour in order to meet the demands of your business. It is important to choose a machine that can handle the volume of production that you require, as investing in a machine that is too small will result in inefficiencies and bottlenecks in your production process.

Another important factor to consider is the speed and efficiency of the automatic 4 head popcorn filling can sealing line. Look for a machine that can fill and seal cans quickly and accurately, as this will help to increase productivity and reduce downtime. A machine that is easy to operate and maintain will also be beneficial, as it will save you time and money in the long run.

In addition to production capacity and efficiency, it is important to consider the quality of the equipment when choosing an automatic 4 head popcorn filling can sealing line. Look for a machine that is made from high-quality materials and is built to last. Investing in a durable and reliable machine will help to ensure that your production process runs smoothly and that your product is consistently sealed to a high standard.

When choosing a popcorn filling can sealing line, it is also important to consider the size and layout of your production facility. Make sure that the machine you choose will fit comfortably in your space and that it can be easily integrated into your existing production line. It is also important to consider any additional features or customization options that may be available, such as different sealing methods or can sizes.

Finally, consider the cost of the automatic 4 head popcorn filling can sealing line when making your decision. While it is important to invest in a high-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices and features from different manufacturers to find the best option for your business.

In conclusion, choosing the right automatic 4 head popcorn filling can sealing line for your business is a crucial decision that will impact the efficiency and productivity of your production process. Consider factors such as production capacity, speed and efficiency, quality, facility size, and cost when making your decision. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your popcorn filling can sealing line is a valuable asset to your business.