In the realm of food packaging, semi-automatic can seamer machines work their magic in ways that often go unnoticed but are incredibly vital.

These machines possess a certain charm that lies in their ability to ensure the freshness and safety of food products. The precision with which they seal the cans is nothing short of magical. Every seam is created with meticulous attention to detail, preventing any air or moisture from penetrating and spoiling the contents inside.

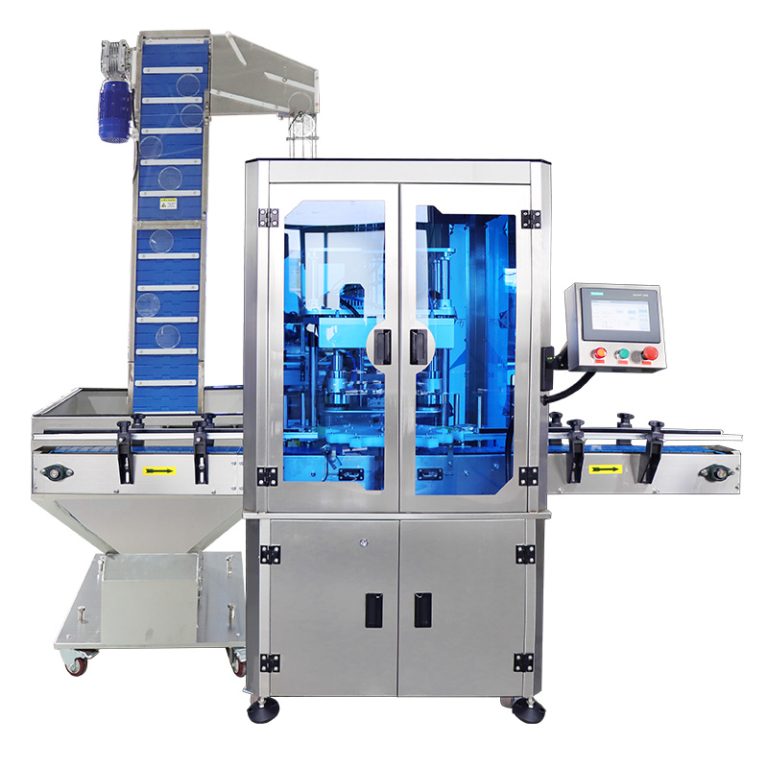

The speed at which semi-automatic can seamer machines operate is like a well-choreographed dance. They swiftly and efficiently seal one can after another, keeping up with the demands of mass production without compromising on quality.

The magic also extends to their adaptability. They can handle a diverse range of can sizes and shapes, accommodating various food items with ease. This flexibility allows food manufacturers to package a wide variety of products, meeting the diverse needs of consumers.

The durability of these machines is yet another aspect of their charm. Built to withstand the rigors of continuous operation, they consistently perform their tasks, providing a reliable solution for food packaging.

Furthermore, the user-friendly interface of semi-automatic can seamer machines simplifies the packaging process. Operators can effortlessly control and monitor the sealing operations, adding to the efficiency and effectiveness of the entire packaging line.

In essence, the magic of semi-automatic can seamer machines lies in their seamless combination of speed, precision, adaptability, and durability. They are the unsung heroes in the world of food packaging, ensuring that the delicious treats we enjoy remain fresh and safe until they reach our tables.