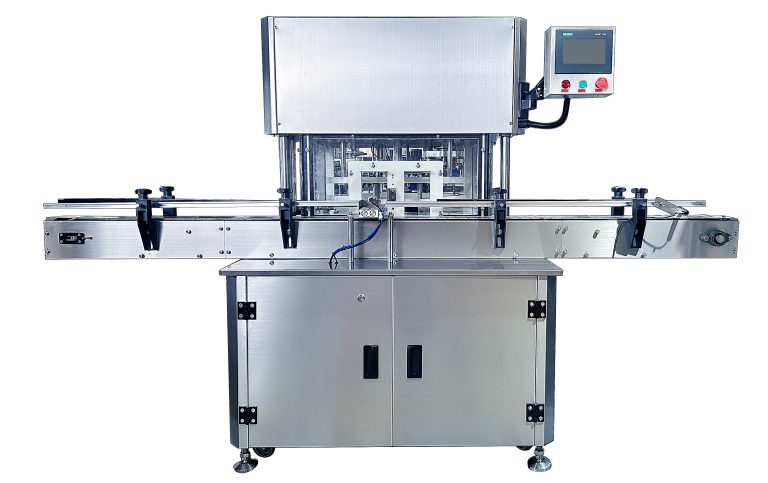

In the world of packaging machinery, the automatic 4 wheel clamping screw capping machine for trigger cap stands out as a remarkable innovation. This advanced device is specifically engineered to handle the precise capping of trigger caps with speed and accuracy.

One of the key highlights of this machine is its 4-wheel clamping mechanism. This feature provides a secure and stable grip on the containers, ensuring that the capping process is carried out smoothly without any slippage or misalignment. The result is a consistently tight and reliable seal on each trigger cap.

The automatic operation of this capping machine brings a significant boost in productivity. It can handle a large volume of containers in a short period, minimizing the time and effort required for capping. This is especially beneficial for high-volume production lines where efficiency is paramount.

The precision engineering of this machine allows for seamless adjustment to accommodate different sizes and types of trigger caps. Whether it’s for cleaning products, cosmetics, or other applications, its adaptability makes it a versatile choice for various industries.

The quality of the capping is consistently top-notch. The screw capping action ensures that the caps are properly tightened, preventing leaks and ensuring the integrity of the packaged product. This not only protects the contents but also enhances the overall presentation and shelf life of the item.

Maintenance of the automatic 4 wheel clamping screw capping machine is relatively straightforward. Regular inspections and timely servicing of key components help to keep the machine operating at peak performance, reducing the risk of breakdowns and maximizing its lifespan.

In conclusion, the automatic 4 wheel clamping screw capping machine is a game-changer in the packaging industry. It combines efficiency, precision, and adaptability to meet the demanding needs of modern packaging operations.

Stay tuned to our blogs for more in-depth looks at the latest advancements in packaging technology!