Advantages of Using an Automatic Capping Machine for Bottles

In the world of manufacturing and packaging, efficiency is key. Companies are constantly looking for ways to streamline their processes and increase productivity. One area where this is particularly important is in the capping of bottles. Whether it’s for food and beverage products, pharmaceuticals, or cosmetics, having a reliable and efficient capping machine can make a big difference in the overall production process.

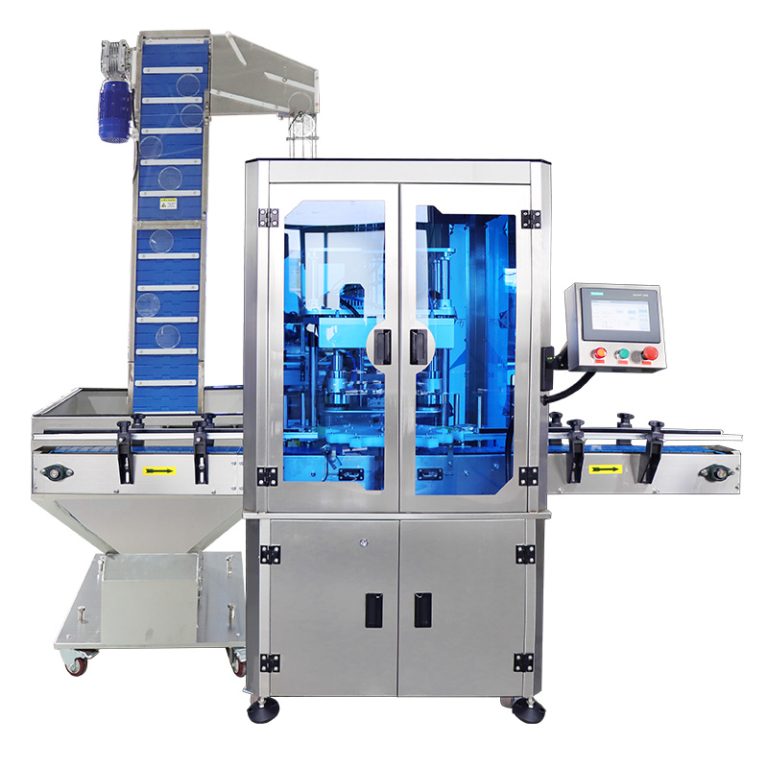

One solution that many companies are turning to is the automatic capping machine. These machines are designed to cap bottles quickly and accurately, without the need for manual labor. This not only saves time and money, but also ensures a consistent and secure seal on each bottle.

One of the biggest advantages of using an automatic capping machine is the speed at which it can cap bottles. These machines are capable of capping hundreds of bottles per minute, far surpassing what a human worker could achieve. This means that production can be ramped up significantly, leading to higher output and increased profits.

Another advantage of automatic capping machines is their accuracy. These machines are designed to cap bottles with precision, ensuring that each bottle is sealed properly. This is particularly important in industries such as pharmaceuticals, where a secure seal is essential to maintaining the integrity of the product.

In addition to speed and accuracy, automatic capping machines also offer a level of consistency that is difficult to achieve with manual labor. These machines are programmed to cap bottles in the same way every time, ensuring that each bottle is sealed in exactly the same manner. This can help to reduce waste and improve overall product quality.

Furthermore, automatic capping machines are easy to operate and require minimal training. Once the machine is set up and programmed, it can run continuously with little oversight. This frees up workers to focus on other tasks, further increasing productivity.

One of the key benefits of using an automatic capping machine is the cost savings it can provide. While the initial investment in a capping machine may be significant, the long-term savings in labor costs and increased efficiency can more than offset this expense. In addition, automatic capping machines are designed to be durable and reliable, meaning that they can provide years of service with minimal maintenance.

Overall, the advantages of using an automatic capping machine for bottles are clear. From increased speed and accuracy to cost savings and improved consistency, these machines offer a simple solution to a common manufacturing challenge. By investing in an automatic capping machine, companies can streamline their production processes, increase output, and ultimately improve their bottom line.