Table of Contents

Benefits of Using Automatic Whey Powder Filling Machine

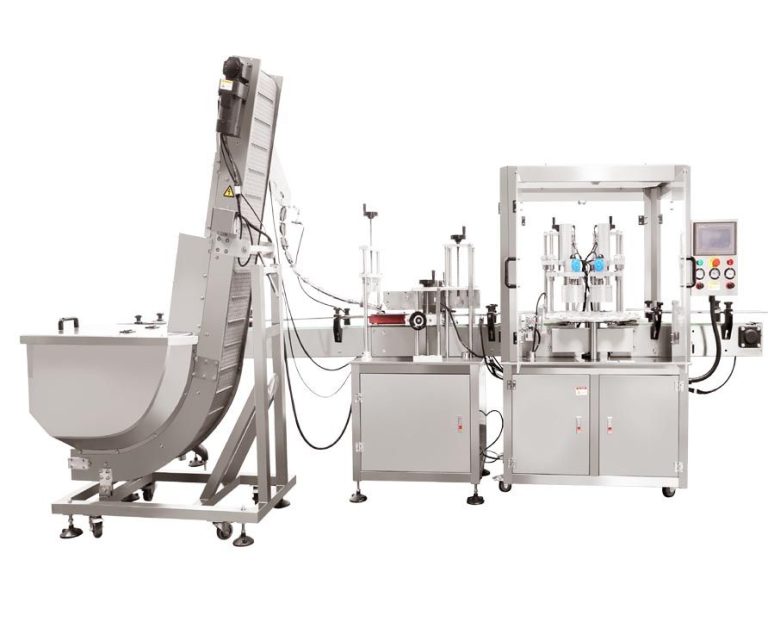

Automatic whey powder filling machines are becoming increasingly popular in the food and beverage industry due to their efficiency and accuracy in filling containers with whey powder. These machines offer a wide range of benefits that can help businesses streamline their production processes and improve overall efficiency.

One of the key benefits of using an automatic whey powder filling machine is the speed at which it can fill containers. These machines are capable of filling a large number of containers in a short amount of time, which can help businesses meet high production demands and increase output. This can be especially beneficial for businesses that have a high volume of whey powder to package and distribute.

In addition to speed, automatic whey powder filling machines also offer a high level of accuracy in filling containers. These machines are equipped with advanced technology that ensures precise measurements of whey powder are dispensed into each container. This can help businesses reduce waste and ensure that each container contains the correct amount of whey powder, which can improve product quality and customer satisfaction.

Another benefit of using an automatic whey powder filling machine is the consistency it provides in filling containers. These machines are programmed to fill containers with the same amount of whey powder each time, which can help businesses maintain a consistent product quality. This can be especially important for businesses that need to adhere to strict quality control standards and ensure that their products meet regulatory requirements.

Furthermore, automatic whey powder filling machines are easy to operate and require minimal training for employees to use. This can help businesses save time and resources on training, as well as reduce the risk of human error in the filling process. Additionally, these machines are designed to be user-friendly and can be easily integrated into existing production lines, making them a convenient and efficient solution for businesses looking to improve their packaging processes.

In conclusion, automatic whey powder filling machines offer a wide range of benefits for businesses in the food and beverage industry. From increased speed and accuracy in filling containers to improved consistency and ease of operation, these machines can help businesses streamline their production processes and improve overall efficiency. By investing in an automatic whey powder filling machine, businesses can save time and resources, reduce waste, and ensure that their products meet high quality standards.

How to Choose the Right Automatic Whey Powder Filling Machine for Your Business

When it comes to packaging powdered products like whey protein, having the right equipment is essential to ensure efficiency and accuracy. An automatic whey powder filling machine can streamline the packaging process and help increase productivity in your business. However, with so many options available on the market, choosing the right machine can be a daunting task. In this article, we will discuss some key factors to consider when selecting an automatic whey powder filling machine for your business.

First and foremost, it is important to consider the production capacity of the machine. Different machines have different capacities, so you need to determine how much whey powder you need to package on a daily basis. This will help you narrow down your options and choose a machine that can meet your production requirements. Additionally, you should consider the speed of the machine. A faster machine can help increase productivity and reduce bottlenecks in the packaging process.

Another important factor to consider is the accuracy of the filling machine. Whey powder is a valuable product, so you want to ensure that each package contains the correct amount of powder. Look for a machine that offers precise filling capabilities to minimize waste and ensure consistency in your products. Additionally, consider the type of packaging you will be using. Some machines are designed to work with specific types of packaging, so make sure the machine you choose is compatible with your packaging materials.

In addition to capacity, speed, accuracy, and compatibility, you should also consider the ease of use and maintenance of the machine. A user-friendly machine can help reduce training time for your staff and minimize the risk of errors during operation. Look for a machine that is easy to set up, operate, and clean to ensure smooth operation in your production facility. Additionally, consider the maintenance requirements of the machine. Regular maintenance is essential to keep the machine running smoothly and prevent breakdowns, so choose a machine that is easy to maintain and service.

When selecting an automatic whey powder filling machine, it is also important to consider the reputation of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines. Reading customer reviews and testimonials can help you gauge the reliability and performance of the machine. Additionally, consider the warranty and after-sales support offered by the manufacturer. A comprehensive warranty and reliable customer support can give you peace of mind knowing that help is available if you encounter any issues with the machine.

In conclusion, choosing the right automatic whey powder filling machine for your business is a crucial decision that can impact the efficiency and productivity of your packaging process. Consider factors such as production capacity, speed, accuracy, compatibility, ease of use, maintenance, and manufacturer reputation when selecting a machine. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you streamline your packaging operations.

Maintenance Tips for Automatic Whey Powder Filling Machine

Automatic whey powder filling machines are essential equipment in the food and beverage industry, as they help streamline the packaging process and ensure accurate filling of whey powder into containers. To ensure the smooth operation of these machines and prevent breakdowns, it is crucial to follow proper maintenance practices. In this article, we will discuss some maintenance tips for automatic whey powder filling machines.

Regular cleaning of the machine is essential to prevent the buildup of whey powder residue, which can lead to contamination and affect the quality of the product. After each production run, the machine should be thoroughly cleaned using a mild detergent and warm water. Pay special attention to areas where whey powder tends to accumulate, such as the filling nozzles and conveyor belts. Regular cleaning will not only prevent contamination but also extend the lifespan of the machine.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, seals, and bearings, and replace them as needed. Inspect the electrical components for any signs of damage or corrosion, and ensure that all connections are secure. Regular inspections will help identify potential issues before they escalate into major problems.

Proper lubrication is crucial for the smooth operation of automatic whey powder filling machines. Make sure to lubricate moving parts, such as conveyor belts and gears, with the appropriate lubricant. Over time, friction can cause these parts to wear out, leading to breakdowns and costly repairs. Regular lubrication will help reduce friction and prolong the lifespan of the machine.

Calibrating the machine regularly is essential to ensure accurate filling of whey powder into containers. Over time, the machine’s settings may drift, leading to underfilling or overfilling of containers. To prevent this, calibrate the machine according to the manufacturer’s instructions. This will help maintain consistent filling accuracy and prevent product wastage.

Regularly check the machine’s sensors and controls to ensure they are functioning properly. Sensors play a crucial role in detecting the presence of containers and controlling the filling process. If a sensor malfunctions, it can lead to misfills and production delays. Regularly test the sensors and controls to ensure they are working correctly and replace any faulty components.

Lastly, it is important to train operators on proper machine operation and maintenance procedures. Ensure that operators are familiar with the machine’s controls, settings, and safety features. Provide training on how to perform routine maintenance tasks, such as cleaning, lubrication, and calibration. Proper training will help prevent operator errors and ensure the efficient operation of the machine.

In conclusion, proper maintenance is essential for the smooth operation of automatic whey powder filling machines. By following these maintenance tips, you can prevent breakdowns, ensure accurate filling of whey powder, and prolong the lifespan of the machine. Regular cleaning, inspections, lubrication, calibration, and operator training are key components of a comprehensive maintenance program. By investing time and effort in maintenance, you can maximize the efficiency and productivity of your automatic whey powder filling machine.