Table of Contents

Benefits of Using Chicken Tin Can Packaging for Long-Term Storage

Chicken tin can packaging is a popular choice for long-term storage of food products, particularly soups. The use of tin cans for packaging chicken and soup offers a range of benefits that make it an ideal option for preserving these perishable items. In this article, we will explore the advantages of using chicken tin can packaging for long-term storage.

One of the key benefits of using tin cans for packaging chicken and soup is their durability. Tin cans are made of sturdy materials that can withstand the rigors of long-term storage, protecting the contents from damage and spoilage. This durability ensures that the food products remain fresh and safe to consume for an extended period of time.

Additionally, tin cans provide an effective barrier against moisture, light, and air, which can all contribute to the deterioration of food products. By sealing chicken and soup in tin cans, manufacturers can prevent these external factors from affecting the quality of the contents, ensuring that they remain fresh and flavorful for an extended period of time.

Furthermore, tin cans are airtight, which helps to preserve the freshness and flavor of the chicken and soup stored inside. The airtight seal prevents oxygen from entering the can, which can lead to oxidation and spoilage of the food products. This ensures that the contents retain their quality and taste for a longer period of time.

In addition to their durability and airtight seal, tin cans are also lightweight and easy to stack and store. This makes them an ideal option for long-term storage, as they can be easily stored in pantries, cupboards, or other storage spaces without taking up a significant amount of space. This convenience makes tin cans a practical choice for consumers looking to stock up on chicken and soup for future use.

Another benefit of using tin cans for packaging chicken and soup is their recyclability. Tin cans are made of recyclable materials, making them an environmentally friendly option for packaging food products. By choosing tin cans for packaging, manufacturers can reduce their environmental impact and contribute to sustainability efforts.

Furthermore, tin cans are cost-effective packaging options for chicken and soup. They are relatively inexpensive to produce, making them a cost-effective choice for manufacturers looking to package their products for long-term storage. This affordability makes tin cans a practical option for businesses looking to maximize their storage capabilities without breaking the bank.

In conclusion, chicken tin can packaging offers a range of benefits for long-term storage of food products, particularly soups. From their durability and airtight seal to their recyclability and cost-effectiveness, tin cans provide an ideal option for preserving chicken and soup for extended periods of time. By choosing tin cans for packaging, manufacturers can ensure that their products remain fresh, flavorful, and safe to consume for consumers looking to stock up on these pantry staples.

How to Optimize Soup Tin Can Packaging Line Efficiency for Increased Production

In the food packaging industry, efficiency is key to meeting production demands and ensuring timely delivery of products to consumers. One area where efficiency can be optimized is in the soup tin can packaging line. By implementing strategies to streamline the packaging process, manufacturers can increase production output and reduce costs. In this article, we will discuss how to optimize soup tin can packaging line efficiency for increased production.

One of the first steps in optimizing a soup tin can packaging line is to evaluate the current process and identify areas for improvement. This may involve conducting a thorough analysis of the packaging line, from the initial filling of the cans to the final sealing and labeling. By identifying bottlenecks or inefficiencies in the process, manufacturers can develop a plan to address these issues and improve overall efficiency.

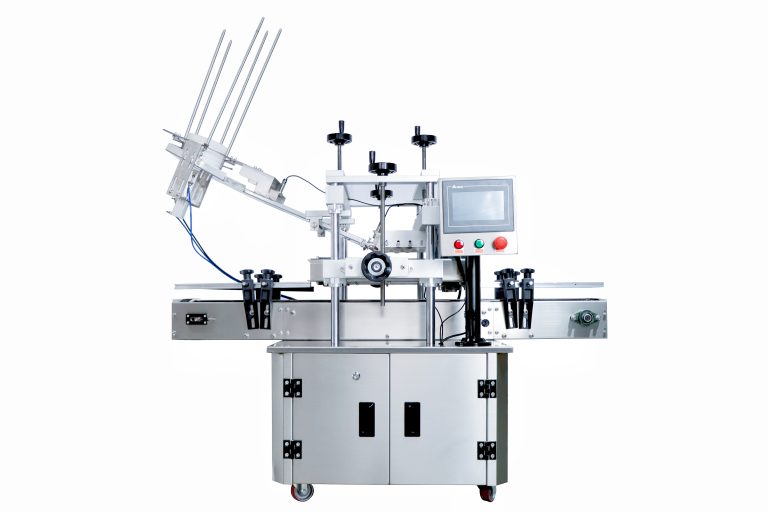

One common area where efficiency can be improved is in the handling of empty cans. By implementing automated systems for feeding empty cans into the packaging line, manufacturers can reduce the need for manual labor and increase the speed at which cans are filled and sealed. Additionally, automated systems can help to reduce the risk of errors or inconsistencies in the packaging process, leading to a higher quality end product.

Another key area for optimizing efficiency in a soup tin can packaging line is in the labeling and coding of cans. By implementing automated labeling and coding systems, manufacturers can reduce the time and labor required to apply labels and codes to cans. This can help to speed up the packaging process and ensure that cans are accurately labeled and coded before they are shipped to retailers.

In addition to implementing automated systems, manufacturers can also optimize efficiency by standardizing packaging processes and training employees on best practices. By developing standardized operating procedures for the packaging line, manufacturers can ensure that all employees are following the same process and that there is consistency in the packaging of cans. This can help to reduce errors and improve overall efficiency in the packaging line.

Furthermore, manufacturers can optimize efficiency by regularly maintaining and servicing packaging equipment. By keeping equipment in good working condition, manufacturers can reduce the risk of breakdowns or malfunctions that can disrupt the packaging process. Regular maintenance can also help to extend the life of equipment and ensure that it is operating at peak efficiency.

In conclusion, optimizing efficiency in a soup tin can packaging line is essential for increasing production output and reducing costs. By evaluating the current process, implementing automated systems, standardizing procedures, and maintaining equipment, manufacturers can streamline the packaging process and improve overall efficiency. By taking steps to optimize efficiency, manufacturers can meet production demands and deliver high-quality products to consumers in a timely manner.