Table of Contents

Benefits of Using Rectangle Candy Taping Around Sealing Machine

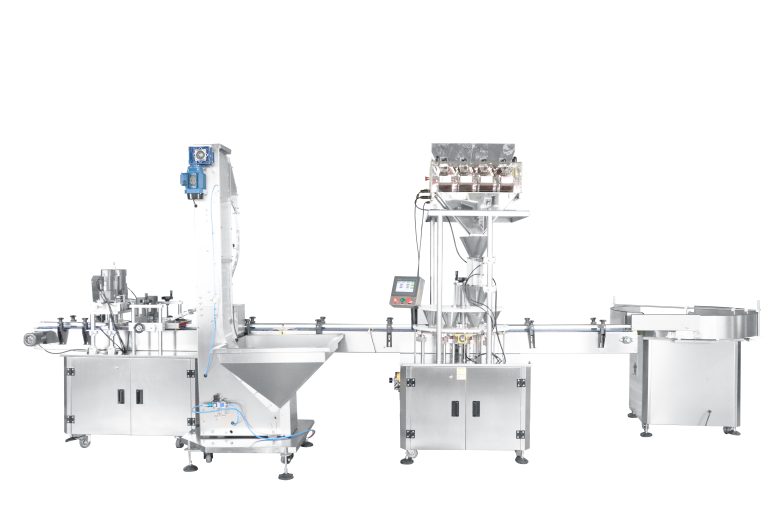

Rectangle candy taping around sealing machines is a common practice in the confectionery industry. This method involves wrapping rectangular-shaped candies in a thin strip of tape before sealing them in packaging. While this may seem like a simple step, there are actually several benefits to using rectangle candy taping around sealing machines.

One of the main advantages of using rectangle candy taping is that it helps to ensure the candies are securely sealed in their packaging. The tape provides an extra layer of protection, helping to prevent the candies from coming loose or becoming damaged during transportation. This is especially important for delicate candies that are prone to breakage.

In addition to providing added protection, rectangle candy taping can also help to enhance the presentation of the candies. The tape can be customized with different colors, patterns, or logos, allowing manufacturers to create a unique and eye-catching look for their products. This can help to attract customers and make the candies stand out on store shelves.

Another benefit of using rectangle candy taping around sealing machines is that it can help to extend the shelf life of the candies. The tape helps to create a barrier that protects the candies from moisture, air, and other contaminants that can cause them to spoil. This can help to ensure that the candies remain fresh and delicious for longer, reducing the risk of waste and increasing customer satisfaction.

Furthermore, rectangle candy taping can also help to improve the efficiency of the sealing process. By using a pre-cut strip of tape that is specifically designed for rectangular candies, manufacturers can save time and reduce waste. This can help to streamline production and increase overall productivity.

Overall, there are many benefits to using rectangle candy taping around sealing machines. From providing added protection and enhancing presentation to extending shelf life and improving efficiency, this method offers a range of advantages for confectionery manufacturers. By incorporating rectangle candy taping into their production process, manufacturers can ensure that their candies are well-protected, visually appealing, and long-lasting.

How to Properly Maintain and Clean Rectangle Candy Taping Around Sealing Machine

Rectangle candy taping around sealing machines are essential tools in the packaging industry, used to seal and package various types of candies. Proper maintenance and cleaning of these machines are crucial to ensure their optimal performance and longevity. In this article, we will discuss the importance of maintaining and cleaning rectangle candy taping around sealing machines, as well as provide some tips on how to do so effectively.

One of the main reasons why it is important to maintain and clean rectangle candy taping around sealing machines is to prevent any contamination of the candies being packaged. Over time, dust, dirt, and other debris can accumulate on the machine, which can then transfer onto the candies during the sealing process. This can not only affect the appearance of the candies but also pose a health risk to consumers. Regular maintenance and cleaning of the machine can help prevent this from happening.

In addition to preventing contamination, proper maintenance and cleaning of rectangle candy taping around sealing machines can also help improve their efficiency and performance. Dust and debris buildup can cause the machine to operate less effectively, leading to slower sealing times and potentially causing damage to the machine itself. By keeping the machine clean and well-maintained, you can ensure that it continues to operate at its best and produce high-quality sealed candies.

So, how can you properly maintain and clean rectangle candy taping around sealing machines? One of the first steps is to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, as well as any buildup of dust or debris. If you notice any issues, address them promptly to prevent further damage to the machine.

When it comes to cleaning the machine, start by unplugging it and removing any excess candy or debris from the taping area. Use a soft brush or cloth to gently wipe down the machine, being careful not to use any harsh chemicals that could damage the machine’s components. Pay special attention to areas where candy residue may have built up, such as the taping rollers and guides.

After cleaning the machine, it is also important to lubricate any moving parts to ensure smooth operation. Use a food-grade lubricant to prevent any contamination of the candies during the sealing process. Be sure to follow the manufacturer’s recommendations for lubrication to avoid damaging the machine.

In conclusion, proper maintenance and cleaning of rectangle candy taping around sealing machines are essential for ensuring their optimal performance and longevity. By regularly inspecting and cleaning the machine, you can prevent contamination of the candies being packaged, improve efficiency, and extend the life of the machine. Follow the tips outlined in this article to keep your rectangle candy taping around sealing machine in top condition and continue producing high-quality sealed candies.