Table of Contents

Benefits of Using Automatic Onion Seed Linear Weigher Filler Equipment

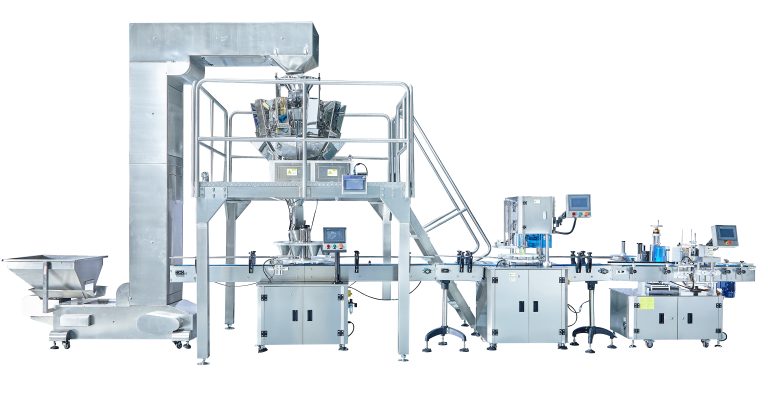

Automatic onion seed linear weigher filler equipment is a valuable tool for businesses in the agriculture and food processing industries. This equipment offers numerous benefits that can help streamline operations, improve efficiency, and increase overall productivity. In this article, we will explore some of the key advantages of using automatic onion seed linear weigher filler equipment.

One of the primary benefits of using automatic onion seed linear weigher filler equipment is its ability to accurately measure and dispense precise amounts of onion seeds. This ensures that each package or container contains the correct weight of seeds, reducing waste and ensuring consistency in product quality. The equipment is equipped with advanced technology that allows for precise measurements, making it a reliable and efficient solution for businesses looking to improve their packaging processes.

In addition to accuracy, automatic onion seed linear weigher filler equipment also offers speed and efficiency. The equipment is designed to quickly and efficiently fill containers with onion seeds, reducing the time and labor required for manual filling. This can help businesses increase their production output and meet customer demand more effectively. With faster filling speeds, businesses can save time and resources, ultimately improving their bottom line.

Another benefit of using automatic onion seed linear weigher filler equipment is its versatility. The equipment can be easily adjusted to accommodate different seed sizes and weights, making it suitable for a wide range of applications. Whether businesses are packaging small or large quantities of onion seeds, the equipment can be customized to meet their specific needs. This flexibility allows businesses to adapt to changing market demands and maintain a competitive edge in the industry.

Furthermore, automatic onion seed linear weigher filler equipment is user-friendly and easy to operate. The equipment is equipped with intuitive controls and interfaces that make it simple for operators to set up and adjust the filling process. This reduces the need for extensive training and allows businesses to quickly integrate the equipment into their existing operations. With minimal downtime and maintenance requirements, businesses can maximize their productivity and focus on other aspects of their operations.

In conclusion, automatic onion seed linear weigher filler equipment offers numerous benefits for businesses in the agriculture and food processing industries. From accuracy and efficiency to versatility and ease of use, this equipment provides a reliable solution for packaging onion seeds. By investing in automatic onion seed linear weigher filler equipment, businesses can improve their packaging processes, increase productivity, and enhance overall efficiency. With its advanced technology and user-friendly design, this equipment is a valuable asset for businesses looking to streamline their operations and stay ahead of the competition.

How to Choose the Right Automatic Onion Seed Linear Weigher Filler Equipment for Your Business

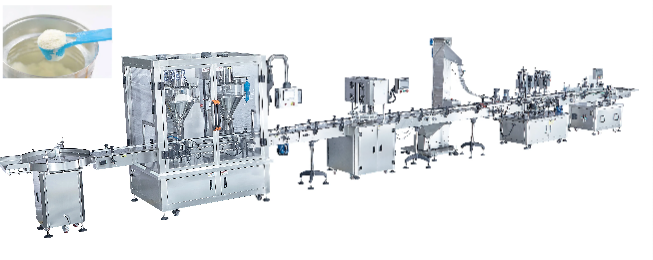

When it comes to choosing the right automatic onion seed linear weigher filler equipment for your business, there are several factors to consider. From the size and capacity of the equipment to the accuracy and speed of the weighing and filling process, it’s important to carefully evaluate your needs and requirements before making a decision.

One of the first things to consider when choosing automatic onion seed linear weigher filler equipment is the size and capacity of the equipment. Depending on the volume of onion seeds you need to weigh and fill, you’ll want to select a machine that can handle the workload efficiently. It’s important to choose a machine that is not only capable of handling your current needs but also has the capacity to accommodate future growth.

In addition to size and capacity, accuracy is another crucial factor to consider when selecting automatic onion seed linear weigher filler equipment. The accuracy of the weighing and filling process can have a significant impact on the quality of your product and the overall efficiency of your operation. Look for equipment that offers precise and consistent weighing and filling capabilities to ensure that your products meet the highest standards.

Speed is also an important consideration when choosing automatic onion seed linear weigher filler equipment. The speed at which the equipment can weigh and fill onion seeds will directly impact the productivity of your operation. Look for equipment that offers fast and efficient weighing and filling capabilities to maximize your output and minimize downtime.

Another important factor to consider when choosing automatic onion seed linear weigher filler equipment is ease of use. The equipment should be user-friendly and easy to operate, with intuitive controls and clear instructions. This will help to minimize training time and ensure that your employees can quickly and easily learn how to use the equipment effectively.

When evaluating different automatic onion seed linear weigher filler equipment options, it’s also important to consider the overall cost of the equipment. While it’s important to invest in high-quality equipment that meets your needs, you’ll also want to ensure that the equipment is cost-effective and offers a good return on investment. Consider factors such as maintenance and operating costs, as well as any additional features or capabilities that may add value to your operation.

In conclusion, choosing the right automatic onion seed linear weigher filler equipment for your business is a crucial decision that can have a significant impact on your productivity and profitability. By carefully evaluating factors such as size, capacity, accuracy, speed, ease of use, and cost, you can select equipment that meets your needs and helps you achieve your business goals. Take the time to research and compare different options to find the best automatic onion seed linear weigher filler equipment for your operation.

Maintenance Tips for Automatic Onion Seed Linear Weigher Filler Equipment

Automatic onion seed linear weigher filler equipment is a crucial component in the onion seed processing industry. It is used to accurately measure and fill onion seeds into packets or containers. The equipment is designed to operate automatically, which means it requires minimal human intervention. However, like any other machine, it requires regular maintenance to ensure it operates efficiently and effectively. In this article, we will discuss some maintenance tips for automatic onion seed linear weigher filler equipment.

Firstly, it is essential to clean the equipment regularly. Onion seeds are small and can easily get stuck in the machine’s moving parts, causing it to malfunction. Therefore, it is crucial to clean the equipment after every use. Use a soft brush or a vacuum cleaner to remove any debris or dust that may have accumulated in the machine. Ensure that you clean the machine thoroughly, including the conveyor belts, hoppers, and weighing scales.

Secondly, it is essential to lubricate the machine’s moving parts regularly. Lubrication helps to reduce friction between the machine’s moving parts, which can cause wear and tear. Use a high-quality lubricant to lubricate the machine’s bearings, chains, and other moving parts. Ensure that you follow the manufacturer’s instructions when lubricating the machine.

Thirdly, it is crucial to inspect the machine’s electrical components regularly. Electrical components such as sensors, switches, and motors are critical to the machine’s operation. Therefore, it is essential to inspect them regularly to ensure they are functioning correctly. Check for any signs of wear and tear, loose connections, or damaged wires. If you notice any issues, contact a qualified technician to repair or replace the faulty components.

Fourthly, it is essential to calibrate the machine regularly. Calibration helps to ensure that the machine is measuring and filling the onion seeds accurately. Use a calibrated weight to check the machine’s accuracy. If you notice any discrepancies, adjust the machine’s settings accordingly. Ensure that you follow the manufacturer’s instructions when calibrating the machine.

Fifthly, it is crucial to train your staff on how to operate the machine correctly. Improper use of the machine can cause damage and reduce its lifespan. Therefore, it is essential to train your staff on how to operate the machine correctly. Ensure that they understand the machine’s functions, safety procedures, and maintenance requirements. Provide them with the necessary protective gear, such as gloves and safety glasses, when operating the machine.

In conclusion, automatic onion seed linear weigher filler equipment is a critical component in the onion seed processing industry. Regular maintenance is essential to ensure that the machine operates efficiently and effectively. Clean the machine regularly, lubricate its moving parts, inspect its electrical components, calibrate it regularly, and train your staff on how to operate it correctly. By following these maintenance tips, you can extend the machine’s lifespan and reduce downtime, which can save you time and money in the long run.