Benefits of Using Camel Milk Powder in Food Production Camel milk powder has been gaining popularity in recent years as a nutritious and versatile ingredient in food production. With its unique composition and health benefits, camel milk powder is being used in a variety of products, from baked goods to…

In the realm of packaging machinery, The Best Tape Around Sealing Machine Manufacturer Gzfharvest stands out for its exceptional offerings and unwavering commitment to quality. The Best Tape Around Sealing Machine Manufacturer Gzfharvest is known for its meticulous engineering. Each tape around sealing machine is designed with precision, ensuring optimal…

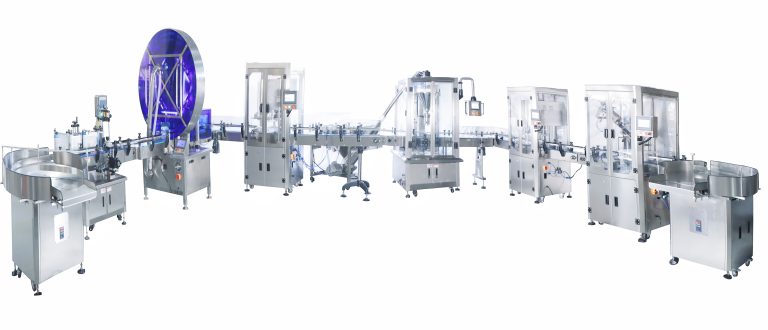

Overview of Automatic Coffee Powder Can Packaging Line Machine Automatic coffee powder can packaging line machines are a crucial component in the coffee production process. These machines are designed to efficiently and accurately package coffee powder into cans, ensuring that the product is sealed and ready for distribution. In this…

Benefits of Using an Automatic Protein Powder Bottle Cans Auger Filling Machine Packaging Line Protein powder has become a popular supplement for fitness enthusiasts and athletes looking to increase their protein intake. With the rise in demand for protein powder products, manufacturers are constantly looking for ways to streamline their…

Automation in Can Packaging Line In the world of manufacturing, efficiency is key. This is especially true in the can packaging industry, where every second counts in getting products out the door and into the hands of consumers. One way to improve efficiency in a can packaging line is through…

The Manual Single Chamber Vacuum Charge Nitrogen Sealing Machine offers a unique and hands-on approach to sealing processes. This Manual Single Chamber Vacuum Charge Nitrogen Sealing Machine is designed for those who require a more controlled and customizable sealing experience. Despite being manual, it provides impressive accuracy and effectiveness. The…