Table of Contents

Benefits of Using Servo Automatic Bottle Screw Capping Machine

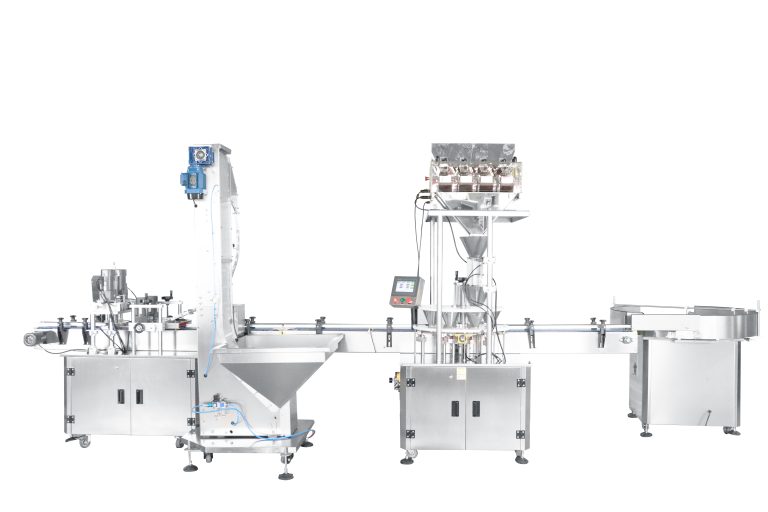

Servo automatic bottle screw capping machines are a valuable tool for businesses in the packaging industry. These machines offer a range of benefits that can help streamline production processes and improve overall efficiency. In this article, we will explore some of the key advantages of using a servo automatic bottle screw capping machine and provide tips on how to use them effectively.

One of the primary benefits of using a servo automatic bottle screw capping machine is its ability to increase production speed. These machines are designed to cap bottles quickly and accurately, allowing businesses to meet high demand without sacrificing quality. By automating the capping process, companies can reduce the time and labor required to cap bottles manually, freeing up resources to focus on other aspects of production.

In addition to improving production speed, servo automatic bottle screw capping machines also offer greater precision and consistency. These machines are equipped with advanced technology that ensures each bottle is capped with the same level of accuracy, reducing the risk of errors and inconsistencies in the final product. This level of precision can help businesses maintain a high level of quality control and ensure customer satisfaction.

Another key benefit of using a servo automatic bottle screw capping machine is its versatility. These machines are capable of capping a wide range of bottle sizes and shapes, making them suitable for a variety of packaging needs. Whether you are capping bottles of different heights, diameters, or materials, a servo automatic bottle screw capping machine can be easily adjusted to accommodate your specific requirements.

To use a servo automatic bottle screw capping machine effectively, it is important to follow a few key steps. First, ensure that the machine is properly set up and calibrated according to the specifications of your bottles. This may involve adjusting the capping head height, speed, and torque settings to ensure a secure and consistent seal.

Next, load the bottles onto the conveyor belt or feeding system of the machine, making sure that they are positioned correctly for capping. Once the bottles are in place, activate the machine and monitor the capping process to ensure that each bottle is capped accurately and securely. If any issues arise during the capping process, such as misaligned caps or inconsistent torque, make adjustments to the machine settings as needed.

After capping is complete, inspect the bottles to ensure that they have been sealed properly. Look for any signs of leakage or damage, and make any necessary adjustments to the machine settings to improve the quality of the capping process. By following these steps and maintaining regular maintenance on your servo automatic bottle screw capping machine, you can ensure that it continues to operate efficiently and effectively for years to come.

In conclusion, servo automatic bottle screw capping machines offer a range of benefits for businesses in the packaging industry. From increased production speed and precision to greater versatility and consistency, these machines can help streamline production processes and improve overall efficiency. By following the tips outlined in this article, you can use a servo automatic bottle screw capping machine effectively and maximize its potential in your packaging operations.

Step-by-Step Guide on Operating Servo Automatic Bottle Screw Capping Machine

Servo automatic bottle screw capping machines are essential equipment in the packaging industry, particularly for companies that deal with bottling products. These machines are designed to efficiently and accurately cap bottles with screw caps, ensuring a tight seal to prevent leakage and contamination. Operating a servo automatic bottle screw capping machine may seem daunting at first, but with the right knowledge and guidance, it can be a straightforward process.

To begin operating a servo automatic bottle screw capping machine, the first step is to ensure that the machine is properly set up and calibrated. This includes adjusting the height of the capping head to match the height of the bottles being capped, as well as setting the torque and speed settings to the appropriate levels for the caps being used. It is crucial to follow the manufacturer’s instructions carefully to avoid any damage to the machine or the bottles.

Once the machine is set up, the next step is to load the bottles onto the conveyor belt or feeding system. It is important to ensure that the bottles are properly aligned and spaced out to prevent jams or misalignments during the capping process. The bottles should be fed into the machine at a consistent rate to maintain efficiency and accuracy.

As the bottles move through the machine, the capping head will automatically apply the screw caps to the bottles. The servo motor in the machine allows for precise control over the capping process, ensuring that each cap is tightened to the correct torque level. This is essential for maintaining the integrity of the seal and preventing any leaks or contamination.

During operation, it is important to monitor the machine closely to ensure that it is running smoothly and that the caps are being applied correctly. Any issues or malfunctions should be addressed immediately to prevent any damage to the machine or the bottles. Regular maintenance and cleaning of the machine are also essential to ensure optimal performance and longevity.

Once the bottles have been capped, they can be removed from the machine and transferred to the next stage of the packaging process. It is important to handle the capped bottles carefully to avoid damaging the caps or compromising the seal. Proper handling and storage of the bottles will help maintain the quality and integrity of the product inside.

In conclusion, operating a servo automatic bottle screw capping machine requires careful attention to detail and adherence to the manufacturer’s instructions. By following a step-by-step guide and maintaining the machine properly, companies can ensure efficient and accurate capping of their bottles. Servo automatic bottle screw capping machines are valuable assets in the packaging industry, providing a reliable and consistent way to cap bottles with screw caps. With the right knowledge and training, operators can make the most of this equipment and ensure the quality and safety of their products.

Troubleshooting Common Issues with Servo Automatic Bottle Screw Capping Machine

Servo automatic bottle screw capping machines are essential equipment in the packaging industry, as they ensure that bottles are securely sealed with caps. However, like any machinery, these capping machines can encounter issues that may affect their performance. In this article, we will discuss some common problems that may arise with servo automatic bottle screw capping machines and how to troubleshoot them effectively.

One of the most common issues with servo automatic bottle screw capping machines is misalignment. This can occur when the bottle and cap are not properly aligned, resulting in caps being placed incorrectly or not at all. To address this issue, it is important to check the alignment of the bottle and cap before running the machine. Adjust the positioning of the bottle and cap guides as needed to ensure proper alignment.

Another common problem with servo automatic bottle screw capping machines is inconsistent torque. Torque refers to the amount of force applied to tighten the cap onto the bottle. Inconsistent torque can result in caps being either too loose or too tight, leading to leaks or difficulty opening the bottle. To troubleshoot this issue, check the torque settings on the machine and adjust them as needed. It is also important to regularly calibrate the torque settings to ensure consistent performance.

Additionally, servo automatic bottle screw capping machines may experience issues with cap feeding. This can occur when caps are not properly fed into the machine, causing delays in the capping process. To address this problem, check the cap feeding mechanism for any obstructions or misalignments. Clean the feeding mechanism regularly to prevent buildup of debris that may impede cap feeding.

Furthermore, servo automatic bottle screw capping machines may encounter issues with cap sealing. This can occur when the sealing head is not properly adjusted or when the sealing material is not applied evenly. To troubleshoot this issue, check the sealing head for any damage or misalignments. Adjust the sealing head as needed to ensure proper sealing of the caps onto the bottles. It is also important to regularly inspect and replace the sealing material to maintain optimal performance.

In conclusion, servo automatic bottle screw capping machines are essential equipment in the packaging industry, but they may encounter common issues that can affect their performance. By troubleshooting these issues effectively, you can ensure that your capping machine operates smoothly and efficiently. Regular maintenance and calibration of the machine are key to preventing these issues from occurring. By following these troubleshooting tips, you can keep your servo automatic bottle screw capping machine in top condition and ensure that your products are securely sealed and packaged.