The Automatic Labeling Machine for Round Bottle is a revolutionary device in the packaging industry. This sophisticated Automatic Labeling Machine for Round Bottle is engineered to precisely apply labels to round bottles with remarkable speed and accuracy. It simplifies the labeling process, eliminating the inconsistencies and inefficiencies associated with manual…

Benefits of Using Rectangle Candy Taping Around Sealing Machine Rectangle candy taping around sealing machines is a common practice in the confectionery industry. This method involves wrapping rectangular-shaped candies in a thin strip of tape before sealing them in packaging. While this may seem like a simple step, there are…

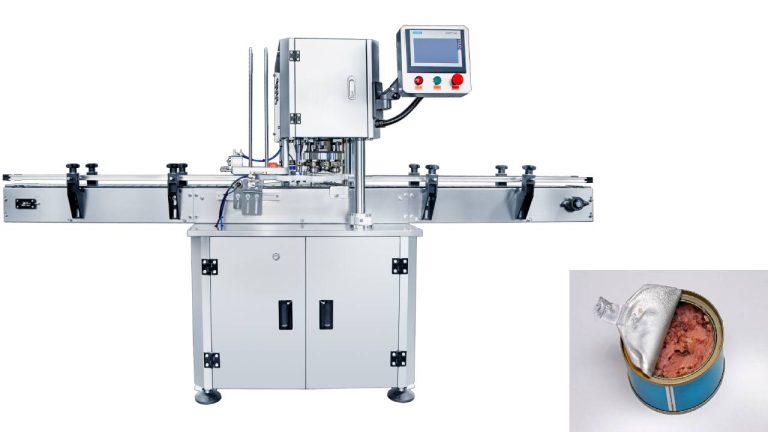

Benefits of Using a Canned Food Can Sealing Machine for Metal Cans Canned food has been a staple in households for decades, providing convenience and long shelf life for a variety of food items. One crucial aspect of canned food production is the sealing of the cans to ensure the…

Benefits of Using Automated Fruit Juice Filling and Capping Machines In the world of food and beverage production, efficiency and consistency are key factors in ensuring a successful operation. When it comes to filling and capping fruit juice bottles, having an automated system in place can greatly improve the overall…

Benefits of Using a Small Round Can Seamer Machine A small round can seamer machine is a valuable piece of equipment for businesses that deal with tin metal cans. These machines are designed to seal cans quickly and efficiently, ensuring that the contents remain fresh and protected from outside contaminants….

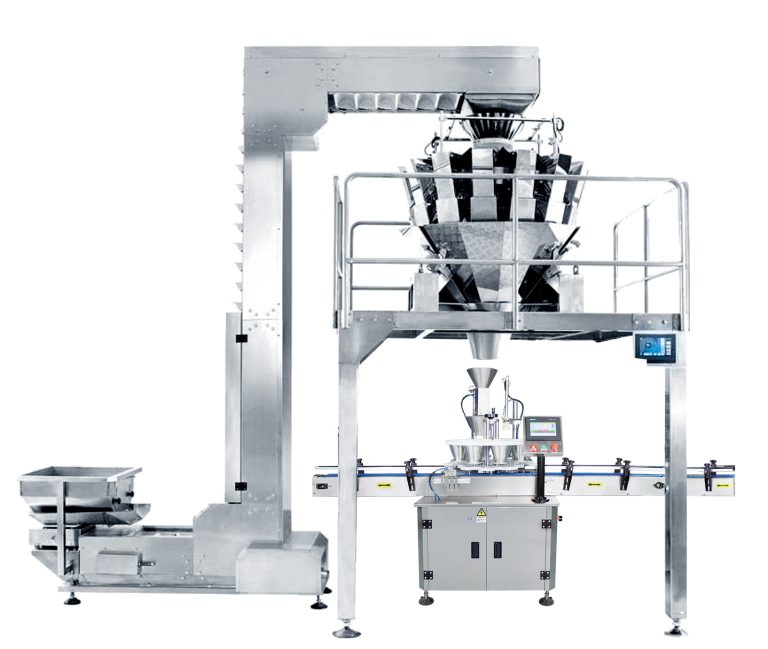

The Automatic Flower Tea Weighing Filling Machine is a game-changer in the world of flower tea packaging. This advanced Automatic Flower Tea Weighing Filling Machine is designed to ensure precise and consistent weighing and filling of flower tea. Its automatic operation eliminates human error and guarantees that each package contains…