Table of Contents

Benefits of Using Nutritional Powder Packing Machine Line

Nutritional powder packing machine lines have become an essential tool for companies in the food and beverage industry. These machines offer a wide range of benefits that can help businesses improve efficiency, reduce costs, and enhance the overall quality of their products.

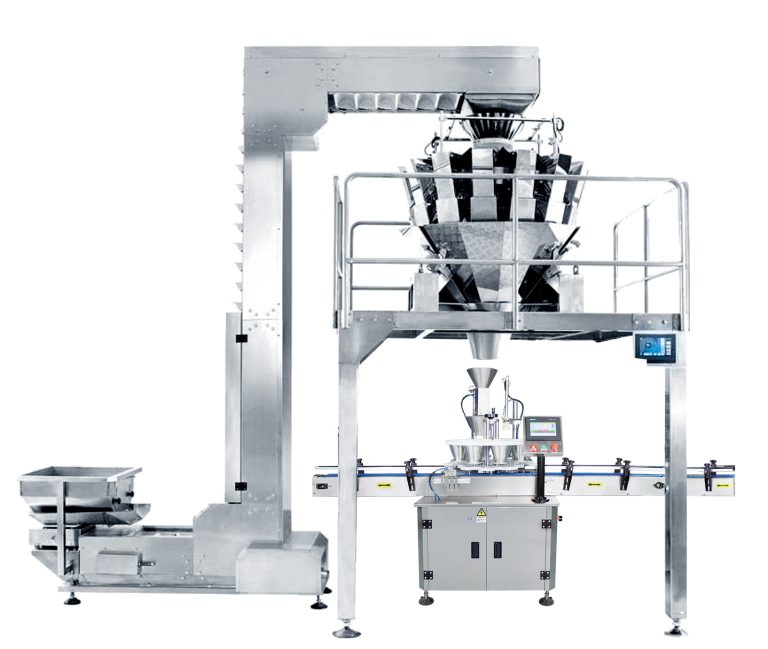

One of the key benefits of using a nutritional powder packing machine line is the increased efficiency it provides. These machines are designed to automate the packaging process, allowing companies to pack large quantities of nutritional powder quickly and accurately. This can help businesses meet high demand and increase their production capacity without the need for additional labor.

In addition to improving efficiency, nutritional powder packing machine lines can also help companies reduce costs. By automating the packaging process, businesses can minimize the risk of human error and waste, leading to lower production costs and higher profit margins. These machines are also designed to be durable and long-lasting, reducing the need for frequent maintenance and replacement, further saving companies money in the long run.

Another benefit of using a nutritional powder packing machine line is the improved quality of the final product. These machines are equipped with advanced technology that ensures precise and consistent packaging, resulting in a more professional and attractive finished product. This can help businesses enhance their brand image and reputation, leading to increased customer satisfaction and loyalty.

Furthermore, nutritional powder packing machine lines offer companies greater flexibility in packaging options. These machines can be customized to accommodate different sizes and types of packaging, allowing businesses to meet the specific needs of their customers. Whether companies are packaging individual servings or bulk quantities, these machines can handle a wide range of packaging requirements with ease.

Additionally, nutritional powder packing machine lines are designed to meet strict hygiene and safety standards. These machines are made from high-quality materials that are easy to clean and sanitize, reducing the risk of contamination and ensuring the safety of the final product. This can help businesses comply with industry regulations and maintain a high level of quality control throughout the packaging process.

Overall, the benefits of using a nutritional powder packing machine line are clear. From increased efficiency and cost savings to improved product quality and flexibility, these machines offer a wide range of advantages for businesses in the food and beverage industry. By investing in a nutritional powder packing machine line, companies can streamline their packaging process, enhance their brand image, and ultimately achieve greater success in the market.

How to Choose the Right Nutritional Powder Packing Machine Line for Your Business

In the fast-paced world of manufacturing, efficiency and accuracy are key factors in determining the success of a business. When it comes to packaging nutritional powder products, having the right equipment can make all the difference. Nutritional powder packing machine lines are designed to streamline the packaging process, ensuring that products are packaged quickly and accurately. However, with so many options available on the market, choosing the right machine line for your business can be a daunting task.

One of the first things to consider when selecting a nutritional powder packing machine line is the type of packaging you require. Different machines are designed to handle different types of packaging, such as pouches, bags, or bottles. It is important to choose a machine line that is compatible with the type of packaging you use for your products. This will ensure that the packaging process runs smoothly and efficiently.

Another important factor to consider is the speed and capacity of the machine line. Depending on the size of your business and the volume of products you need to package, you may require a machine line that can handle a high volume of products at a fast pace. It is important to choose a machine line that can keep up with the demands of your business to avoid bottlenecks in the packaging process.

In addition to speed and capacity, it is also important to consider the accuracy and precision of the machine line. Nutritional powder products often require precise measurements to ensure that each package contains the correct amount of product. Choosing a machine line that is equipped with accurate measuring and filling mechanisms will help to ensure that your products are packaged correctly every time.

When selecting a nutritional powder packing machine line, it is also important to consider the level of automation that is required for your business. Fully automated machine lines are designed to minimize human intervention in the packaging process, reducing the risk of errors and increasing efficiency. However, fully automated machine lines can be more expensive than semi-automated or manual machine lines. It is important to weigh the cost of automation against the benefits it can provide for your business.

Finally, it is important to consider the reputation and reliability of the manufacturer when choosing a nutritional powder packing machine line. Look for manufacturers with a proven track record of producing high-quality, reliable machines. Reading reviews and testimonials from other customers can help you gauge the quality of the machine line and the level of customer support provided by the manufacturer.

In conclusion, choosing the right nutritional powder packing machine line for your business is a crucial decision that can have a significant impact on the efficiency and success of your packaging process. By considering factors such as the type of packaging required, speed and capacity, accuracy and precision, level of automation, and the reputation of the manufacturer, you can make an informed decision that will benefit your business in the long run. Investing in a high-quality machine line will not only improve the efficiency of your packaging process but also help to ensure the quality and consistency of your products.

Tips for Maintaining and Cleaning Nutritional Powder Packing Machine Line

Nutritional powder packing machines are essential equipment in the food and pharmaceutical industries. They are used to efficiently package powdered products such as protein powders, meal replacements, and vitamins. To ensure the smooth operation of these machines and maintain the quality of the products being packaged, it is crucial to regularly clean and maintain them. In this article, we will provide some tips for maintaining and cleaning a nutritional powder packing machine line.

First and foremost, it is important to follow the manufacturer’s guidelines for cleaning and maintenance. Each machine may have specific requirements, so it is essential to refer to the user manual for detailed instructions. Regular cleaning and maintenance will not only prolong the life of the machine but also ensure that it operates at peak efficiency.

One of the most critical aspects of maintaining a nutritional powder packing machine line is to regularly clean the machine after each use. This will prevent the buildup of powder residue, which can lead to contamination and affect the quality of the products being packaged. Use a soft brush or cloth to remove any powder residue from the machine’s surfaces, including the hopper, conveyor belts, and sealing mechanisms.

In addition to regular cleaning, it is also essential to perform routine maintenance on the machine. This includes checking for any loose or damaged parts, lubricating moving components, and inspecting the machine for any signs of wear and tear. By addressing any issues promptly, you can prevent costly repairs and downtime in the future.

Another important tip for maintaining a nutritional powder packing machine line is to calibrate the machine regularly. This involves adjusting the machine’s settings to ensure that it accurately measures and dispenses the correct amount of powder. Calibration is crucial for maintaining the consistency and accuracy of the packaged products, so it is essential to perform this task regularly.

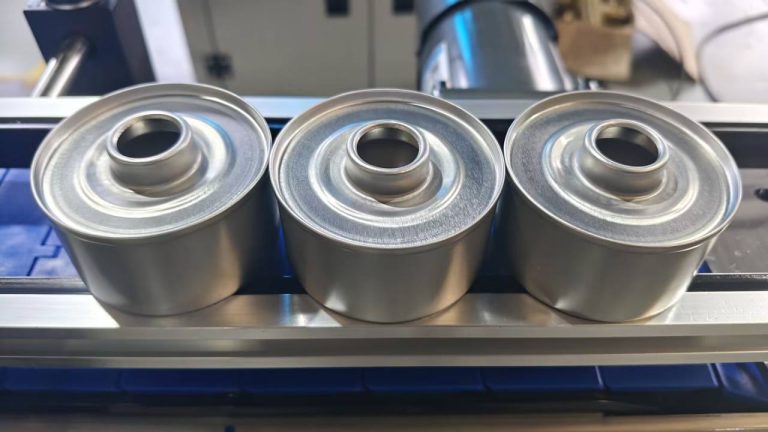

Furthermore, it is essential to use high-quality packaging materials to ensure the integrity of the products being packaged. Low-quality materials can lead to leaks, contamination, and spoilage, which can affect the quality of the products and damage the machine. Invest in durable packaging materials that are compatible with the machine to ensure smooth operation and high-quality packaging.

Lastly, it is crucial to train your staff on proper cleaning and maintenance procedures for the nutritional powder packing machine line. Ensure that all operators are familiar with the machine’s operation and maintenance requirements to prevent any mishaps or accidents. By providing adequate training, you can ensure that the machine is properly cared for and operated, leading to optimal performance and product quality.

In conclusion, maintaining and cleaning a nutritional powder packing machine line is essential for ensuring the quality of the packaged products and prolonging the life of the machine. By following the tips outlined in this article, you can keep your machine in top condition and prevent any issues that may arise from neglect or improper maintenance. Remember to refer to the manufacturer’s guidelines, perform regular cleaning and maintenance, calibrate the machine regularly, use high-quality packaging materials, and train your staff on proper procedures. By taking these steps, you can ensure that your nutritional powder packing machine line operates efficiently and produces high-quality products.