Increased Efficiency in Snack Food Packaging with Automatic Dual Head Tin Can Closing Machine In the fast-paced world of snack food production, efficiency is key. Manufacturers are constantly looking for ways to streamline their processes and increase output without sacrificing quality. One area where significant improvements can be made is…

Benefits of Using Organic Rice in Tin Cans Organic rice has become increasingly popular in recent years as consumers become more conscious of the food they eat and its impact on their health and the environment. One of the ways in which organic rice is being packaged and preserved is…

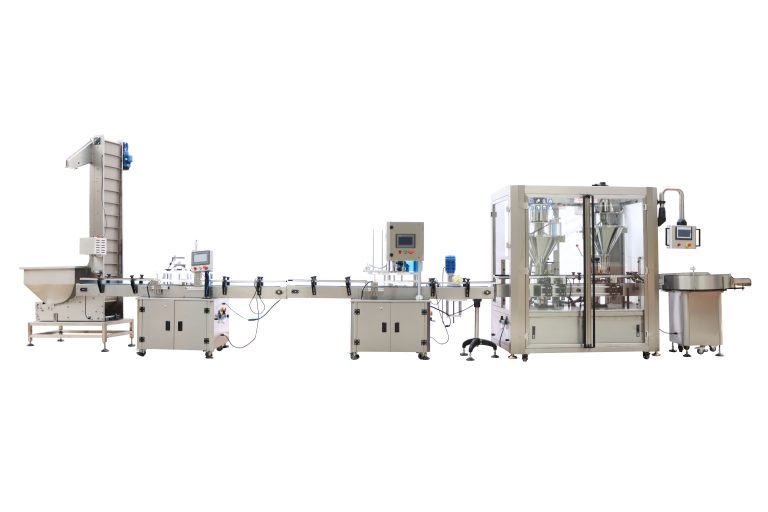

Benefits of Using Milk Powder Can Filling Machine in Dairy Industry Milk powder can filling machines have become an essential tool in the dairy industry, streamlining the process of packaging milk powder into cans efficiently and accurately. These machines are designed to handle the delicate nature of milk powder, ensuring…

Benefits of Using Auger Powder Filling Machines in Production Lines Auger powder filling machines have become an essential tool in various production lines across industries. These machines offer numerous benefits that help streamline the production process and improve efficiency. In this article, we will explore the advantages of using auger…

Advancements in Can Sealing Machine Technology The can sealing machine market has seen significant growth in recent years, driven by the increasing demand for packaged beverages and food products. As technology continues to advance, the future development trend of can sealing machines is expected to focus on improving efficiency, reliability,…

Benefits of Using Canned Seafood Vacuum Can Seaming Machine Canned seafood is a popular choice for many consumers due to its convenience, long shelf life, and ability to retain the freshness of the seafood. In order to ensure that the canned seafood remains fresh and safe for consumption, it is…