Table of Contents

Benefits of Using Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine

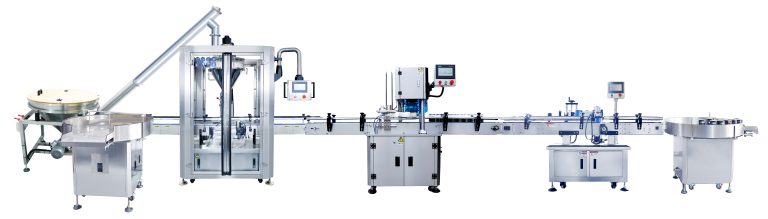

Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine is a revolutionary piece of equipment that has transformed the packaging industry. This machine offers a wide range of benefits that make it a valuable investment for businesses looking to streamline their production processes and improve efficiency.

One of the key benefits of using the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine is its ability to increase production speed. This machine is designed to automatically clamp, screw, and cap plastic jars in a fraction of the time it would take a human operator to do the same task. This means that businesses can produce more products in less time, leading to increased output and higher profits.

In addition to increasing production speed, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine also helps to improve the overall quality of the finished products. By automating the clamping, screwing, and capping process, this machine ensures that each jar is sealed correctly and securely. This helps to prevent leaks and contamination, ensuring that the products reach consumers in perfect condition.

Another benefit of using the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine is its versatility. This machine is capable of handling a wide range of jar sizes and shapes, making it suitable for use in a variety of industries. Whether you are packaging food products, cosmetics, or pharmaceuticals, this machine can be easily adjusted to meet your specific needs.

Furthermore, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine is incredibly easy to operate. With user-friendly controls and a simple setup process, businesses can quickly integrate this machine into their production line without the need for extensive training or specialized knowledge. This helps to minimize downtime and ensure that production runs smoothly.

In addition to its ease of use, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine also offers a high level of reliability. This machine is built to last, with durable components that are designed to withstand the rigors of continuous use. This means that businesses can rely on this machine to perform consistently and efficiently, day in and day out.

Finally, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine can help businesses save money in the long run. By increasing production speed, improving product quality, and reducing the risk of human error, this machine can help businesses cut costs and improve their bottom line. Additionally, the versatility and reliability of this machine mean that businesses can continue to use it for years to come, making it a smart investment for the future.

In conclusion, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine offers a wide range of benefits that make it a valuable asset for businesses in the packaging industry. From increasing production speed and improving product quality to its versatility, ease of use, reliability, and cost-saving potential, this machine has the potential to transform the way businesses package their products. If you are looking to streamline your production processes and improve efficiency, the Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine is definitely worth considering.

How to Choose the Right Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine for Your Business

In today’s fast-paced manufacturing industry, efficiency and precision are key factors in ensuring the success of your business. When it comes to packaging products in plastic jars, having the right equipment can make all the difference. One essential piece of machinery that can streamline your production process is an automatic plastic jar four wheels clamping screwing capping machine. This machine is designed to automatically clamp, screw, and cap plastic jars with ease, saving you time and labor costs. However, with so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting an automatic plastic jar four wheels clamping screwing capping machine for your business.

First and foremost, it is important to consider the size and shape of the plastic jars that you will be using. Different machines are designed to accommodate different sizes and shapes of jars, so it is crucial to choose a machine that is compatible with your specific packaging needs. Additionally, consider the speed and efficiency of the machine. Look for a machine that can cap jars quickly and accurately to keep up with the demands of your production line.

Another important factor to consider is the level of automation that the machine offers. Some machines are fully automatic, while others require manual intervention at certain stages of the capping process. Depending on the size of your operation and your budget, you may opt for a fully automatic machine to maximize efficiency and minimize labor costs. However, if you have a smaller operation or limited budget, a semi-automatic machine may be more suitable.

In addition to automation, consider the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to operate, with clear instructions and minimal downtime for maintenance. A machine that is easy to maintain will help to minimize production disruptions and ensure that your business runs smoothly.

Furthermore, consider the reputation and reliability of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines that are built to last. Reading customer reviews and testimonials can also help you gauge the reliability and performance of a particular machine.

Lastly, consider your budget and return on investment. While it may be tempting to opt for the cheapest machine available, it is important to consider the long-term costs and benefits of the machine. Investing in a high-quality machine may require a larger upfront investment, but it can pay off in the long run by increasing efficiency, reducing labor costs, and improving overall productivity.

In conclusion, choosing the right automatic plastic jar four wheels clamping screwing capping machine for your business is a crucial decision that can have a significant impact on your production process. By considering factors such as jar size, speed, automation, ease of use, manufacturer reputation, and budget, you can make an informed decision that will benefit your business in the long run. Take the time to research and compare different machines to find the one that best suits your specific needs and requirements. With the right machine in place, you can streamline your production process, increase efficiency, and ultimately, boost your bottom line.

Maintenance Tips for Automatic Plastic Jar Four Wheels Clamping Screwing Capping Machine

Maintaining an automatic plastic jar four wheels clamping screwing capping machine is essential to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality products consistently. In this article, we will discuss some maintenance tips to help you keep your automatic capping machine in top condition.

First and foremost, it is crucial to follow the manufacturer’s guidelines for maintenance and servicing. These guidelines are designed to help you understand the specific needs of your machine and how to address them effectively. Regularly scheduled maintenance tasks, such as cleaning, lubricating, and inspecting the machine, should be performed according to the manufacturer’s recommendations.

One of the most important maintenance tasks for an automatic capping machine is cleaning. Regular cleaning helps prevent the buildup of dirt, debris, and other contaminants that can affect the machine’s performance. It is essential to clean the machine thoroughly after each use, paying special attention to areas that come into contact with the product, such as the clamping and screwing mechanisms.

In addition to cleaning, lubricating the moving parts of the machine is also crucial for its proper functioning. Lubrication helps reduce friction and wear on the machine’s components, extending their lifespan and ensuring smooth operation. It is important to use the correct type and amount of lubricant recommended by the manufacturer to avoid damage to the machine.

Inspecting the machine regularly is another essential maintenance task. By inspecting the machine for signs of wear, damage, or malfunction, you can identify and address potential issues before they escalate into more significant problems. Pay attention to any unusual noises, vibrations, or changes in the machine’s performance, as these could indicate underlying issues that need to be addressed.

Replacing worn or damaged parts promptly is also crucial for maintaining the performance of an automatic capping machine. Over time, the machine’s components may wear out or become damaged due to regular use. It is essential to replace these parts with genuine, high-quality replacements to ensure the machine’s continued reliability and efficiency.

In addition to regular maintenance tasks, it is essential to train your staff on how to operate the automatic capping machine correctly. Proper training helps prevent operator errors that can lead to machine damage or malfunction. Make sure that your staff understands how to use the machine safely and efficiently, following all safety guidelines and procedures.

Lastly, keeping detailed records of maintenance tasks and repairs can help you track the machine’s performance and identify any recurring issues. By maintaining a maintenance log, you can monitor the machine’s condition over time and schedule preventive maintenance tasks accordingly. This proactive approach can help you avoid unexpected breakdowns and downtime, ensuring that your production line runs smoothly.

In conclusion, regular maintenance is essential for keeping an automatic plastic jar four wheels clamping screwing capping machine in top condition. By following the manufacturer’s guidelines, cleaning, lubricating, inspecting, and replacing worn parts, you can ensure that your machine operates efficiently and produces high-quality products consistently. Training your staff on proper machine operation and keeping detailed maintenance records are also crucial for maintaining the machine’s performance and longevity. By following these maintenance tips, you can maximize the lifespan of your automatic capping machine and optimize your production process.