Table of Contents

Benefits of Using Sesame Chili Oil Filling and Sealing Machine Line in Food Production

Sesame chili oil is a popular condiment in many Asian cuisines, known for its rich flavor and spicy kick. In recent years, the demand for sesame chili oil has been on the rise, leading to an increase in production. To meet this growing demand, many food manufacturers are turning to automated filling and sealing machines to streamline their production process.

One of the main benefits of using a sesame chili oil filling and sealing machine line in food production is efficiency. These machines are designed to fill and seal bottles or containers with precision and speed, significantly reducing the time and labor required for manual filling. This not only increases productivity but also ensures consistency in product quality, as the machine can accurately dispense the correct amount of oil every time.

In addition to efficiency, using a filling and sealing machine line can also improve food safety. By automating the filling and sealing process, the risk of contamination from human handling is minimized. This is especially important when working with sensitive products like sesame chili oil, which can spoil easily if exposed to bacteria or other contaminants. With a machine line, the entire process is enclosed and controlled, reducing the chances of contamination and ensuring the safety of the final product.

Another benefit of using a sesame chili oil filling and sealing machine line is cost savings. While the initial investment in a machine line may be significant, the long-term savings in labor costs and product wastage can be substantial. By automating the production process, manufacturers can produce larger quantities of oil in a shorter amount of time, leading to economies of scale and lower production costs per unit.

Furthermore, using a filling and sealing machine line can also improve the overall quality of the product. These machines are equipped with advanced technology that can accurately measure and dispense the oil, ensuring that each bottle or container is filled to the correct level. This level of precision is difficult to achieve with manual filling methods, where human error can lead to inconsistencies in product quality. By using a machine line, manufacturers can guarantee that every bottle of sesame chili oil meets their quality standards, leading to greater customer satisfaction and loyalty.

Overall, the benefits of using a sesame chili oil filling and sealing machine line in food production are clear. From increased efficiency and cost savings to improved food safety and product quality, these machines offer a range of advantages for manufacturers looking to scale up their production. By investing in a machine line, food manufacturers can meet the growing demand for sesame chili oil while maintaining high standards of quality and safety.

Step-by-Step Guide on How to Operate a Sesame Chili Oil Filling and Sealing Machine Line

Sesame chili oil is a popular condiment in many Asian cuisines, known for its rich flavor and spicy kick. To meet the demand for this product, many manufacturers use filling and sealing machine lines to efficiently package the oil into bottles or containers. In this article, we will provide a step-by-step guide on how to operate a sesame chili oil filling and sealing machine line.

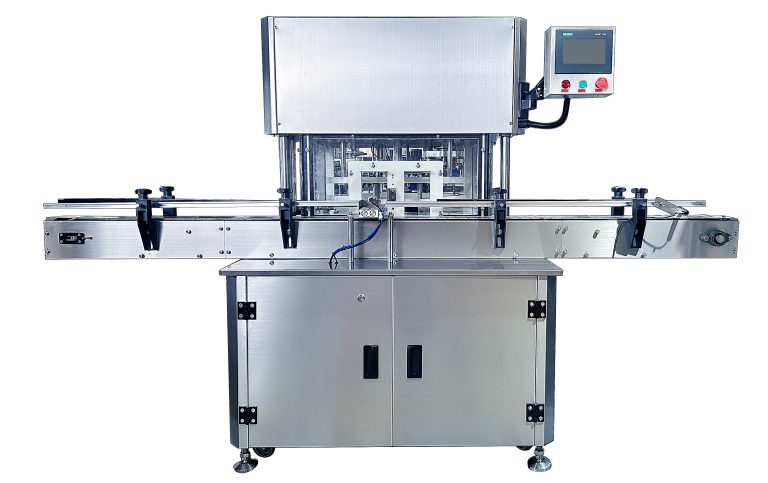

First and foremost, it is essential to ensure that the machine is properly set up and calibrated before starting the production process. This includes checking the alignment of the filling nozzles, adjusting the filling volume, and ensuring that the sealing mechanism is functioning correctly. It is also important to make sure that the machine is clean and free of any debris that could contaminate the oil.

Once the machine is set up, the next step is to prepare the sesame chili oil for filling. This involves heating the oil to the appropriate temperature to ensure that it flows smoothly through the filling nozzles. It is also important to filter the oil to remove any impurities that could clog the machine or affect the quality of the final product.

After the oil is prepared, it is time to start the filling process. The operator should carefully position the bottles or containers on the conveyor belt, making sure that they are properly aligned with the filling nozzles. The machine will then automatically dispense the correct amount of oil into each container, ensuring that the fill level is consistent across all bottles.

Once the bottles are filled, the next step is to seal them to prevent any leakage or contamination. The sealing mechanism on the machine will apply a cap or lid to each bottle, ensuring that the oil is securely contained. It is important to check the seals regularly to ensure that they are tight and secure.

As the bottles are filled and sealed, they will be conveyed to the labeling and packaging station. Here, labels can be applied to the bottles, and they can be packed into boxes or crates for shipping. It is important to ensure that the labels are applied accurately and that the packaging is secure to prevent any damage during transportation.

Throughout the production process, it is important to monitor the machine and make any necessary adjustments to ensure that it is operating efficiently. This includes checking the fill level, inspecting the seals, and troubleshooting any issues that may arise. Regular maintenance and cleaning of the machine are also essential to ensure that it continues to operate smoothly.

In conclusion, operating a sesame chili oil filling and sealing machine line requires careful attention to detail and a thorough understanding of the machine’s operation. By following the steps outlined in this guide, manufacturers can ensure that their products are filled and sealed efficiently and accurately, meeting the demand for this popular condiment.