Table of Contents

Benefits of Using Automatic Powder Filling Machine for Talcum Powder

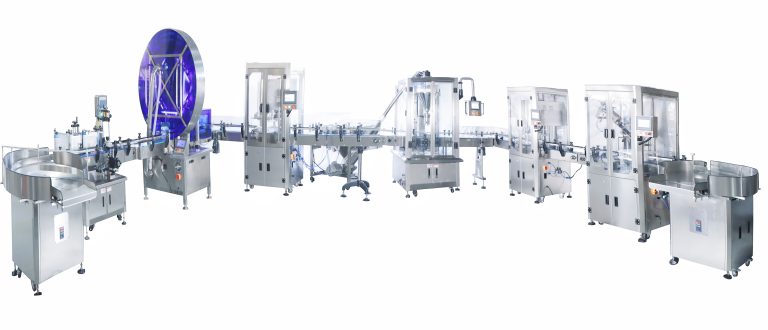

Talcum powder is a common household product that is used for a variety of purposes, from keeping skin dry to preventing chafing. As such, there is a high demand for talcum powder in the market, and manufacturers need efficient and reliable ways to package and distribute this product. One solution to this need is the automatic powder filling machine, which offers a range of benefits for businesses looking to streamline their production processes.

One of the key benefits of using an automatic powder filling machine for talcum powder is its efficiency. These machines are designed to fill containers with precise amounts of powder quickly and accurately, reducing the risk of product waste and ensuring consistent product quality. This can help businesses save time and money by increasing their production output and minimizing the need for manual labor.

In addition to efficiency, automatic powder filling machines also offer improved accuracy compared to manual filling methods. These machines are equipped with advanced technology that allows them to measure and dispense the exact amount of powder needed for each container, ensuring that every product meets the required specifications. This level of precision can help businesses maintain high standards of quality control and customer satisfaction.

Furthermore, automatic powder filling machines are designed to be user-friendly and easy to operate. With intuitive controls and automated processes, these machines can be operated by a single operator, reducing the need for additional manpower and training. This can help businesses streamline their production processes and increase overall productivity.

Another benefit of using an automatic powder filling machine for talcum powder is its versatility. These machines can be customized to accommodate a wide range of container sizes and shapes, making them suitable for a variety of packaging requirements. Whether businesses need to fill bottles, jars, or pouches, automatic powder filling machines can be adjusted to meet their specific needs.

Moreover, automatic powder filling machines are designed to be durable and reliable, with minimal maintenance requirements. This can help businesses reduce downtime and increase operational efficiency, ensuring that production runs smoothly and without interruptions. Additionally, these machines are built to meet industry standards for safety and hygiene, making them a reliable and compliant choice for businesses in the pharmaceutical, cosmetic, and food industries.

Overall, the benefits of using an automatic powder filling machine for talcum powder are clear. From increased efficiency and accuracy to improved productivity and versatility, these machines offer a range of advantages for businesses looking to streamline their production processes and meet the demands of the market. By investing in an automatic powder filling machine, businesses can enhance their operations, reduce costs, and deliver high-quality products to their customers.

How to Choose the Right Automatic Powder Filling Machine for Talcum Powder

Automatic powder filling machines are essential equipment for industries that require precise and efficient packaging of powdered products like talcum powder. These machines are designed to accurately fill containers with a predetermined amount of powder, ensuring consistency and reducing waste. When choosing the right automatic powder filling machine for talcum powder, there are several factors to consider to ensure optimal performance and productivity.

One of the most important factors to consider when selecting an automatic powder filling machine is the type of powder being filled. Talcum powder is a fine, lightweight powder that can be easily dispersed in the air. Therefore, it is crucial to choose a machine that is specifically designed to handle talcum powder and prevent dust from escaping into the environment. Look for a machine with features such as dust collection systems, sealed filling chambers, and anti-static components to minimize dust emissions and ensure a clean working environment.

Another important consideration when choosing an automatic powder filling machine for talcum powder is the filling speed and accuracy. Talcum powder is a high-volume product that requires fast and precise filling to meet production demands. Look for a machine with a high filling speed and accuracy rate to ensure efficient packaging and minimize downtime. Additionally, consider the machine’s capacity and output rate to ensure it can meet your production requirements without compromising on quality.

In addition to speed and accuracy, it is essential to consider the versatility and flexibility of the automatic powder filling machine. Talcum powder may be packaged in various container sizes and shapes, so choose a machine that can accommodate different packaging requirements. Look for a machine with adjustable filling heads, changeable filling nozzles, and customizable settings to easily switch between different packaging formats and sizes. This flexibility will allow you to adapt to changing market demands and expand your product offerings without investing in additional equipment.

When selecting an automatic powder filling machine for talcum powder, it is also important to consider the machine’s ease of use and maintenance requirements. Look for a machine with user-friendly controls, intuitive interfaces, and easy-to-clean components to streamline operation and reduce downtime. Additionally, choose a machine from a reputable manufacturer with a proven track record of reliability and customer support to ensure long-term performance and minimal maintenance costs.

Finally, consider the overall cost of the automatic powder filling machine, including initial investment, operating costs, and potential return on investment. Compare different machines based on their features, performance, and price to find the best value for your budget. Keep in mind that investing in a high-quality machine may require a higher upfront cost but can result in long-term savings through increased productivity, reduced waste, and improved product quality.

In conclusion, choosing the right automatic powder filling machine for talcum powder is a critical decision that can impact your production efficiency and product quality. Consider factors such as powder type, filling speed and accuracy, versatility, ease of use, and cost when selecting a machine to ensure optimal performance and productivity. By carefully evaluating your requirements and comparing different machines, you can find the perfect solution to meet your talcum powder packaging needs.

Maintenance Tips for Automatic Powder Filling Machine for Talcum Powder

Automatic powder filling machines are essential equipment in the manufacturing industry, especially for products like talcum powder. These machines are designed to accurately fill containers with a predetermined amount of powder, ensuring consistency and efficiency in the production process. However, like any other machinery, automatic powder filling machines require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tips for automatic powder filling machines is to regularly clean and sanitize the equipment. Talcum powder can be prone to clumping and clogging, which can affect the accuracy of the filling process. By cleaning the machine regularly, you can prevent build-up and ensure that the powder flows smoothly through the equipment.

In addition to cleaning, it is also important to inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, seals, and nozzles, and replace them as needed. Regular inspections can help prevent breakdowns and ensure that the machine operates efficiently.

Another maintenance tip for automatic powder filling machines is to lubricate moving parts regularly. Proper lubrication can help reduce friction and wear on the machine, extending its lifespan and preventing costly repairs. Be sure to use the appropriate lubricant for the specific components of the machine to avoid damage.

Calibrating the machine is also crucial for maintaining accuracy in the filling process. Over time, the machine may become misaligned or lose calibration, leading to inaccuracies in the amount of powder dispensed. Regularly calibrating the machine ensures that it continues to fill containers with the correct amount of powder, reducing waste and ensuring product quality.

In addition to these maintenance tips, it is important to follow the manufacturer’s guidelines for operating and maintaining the automatic powder filling machine. Each machine is unique and may have specific requirements for maintenance and care. By following the manufacturer’s recommendations, you can ensure that the machine operates at its best and avoid unnecessary downtime.

Lastly, it is important to train operators on how to properly use and maintain the automatic powder filling machine. Proper training can help prevent accidents and damage to the equipment, as well as ensure that the machine is operated efficiently. Operators should be familiar with the machine’s functions, safety protocols, and maintenance procedures to ensure smooth operation.

In conclusion, regular maintenance is essential for ensuring the optimal performance of automatic powder filling machines for talcum powder. By following these maintenance tips, you can prolong the lifespan of the equipment, prevent breakdowns, and ensure accurate and efficient filling of containers. Remember to clean, inspect, lubricate, calibrate, and train operators to keep your automatic powder filling machine in top condition.